A case for a new LED technology that promises to change the way growers look at lighting.

Warren Buffet famously said that there are fundamental rules to follow as an entrepreneur.

- Never lose money.

- Never forget Rule No.1.

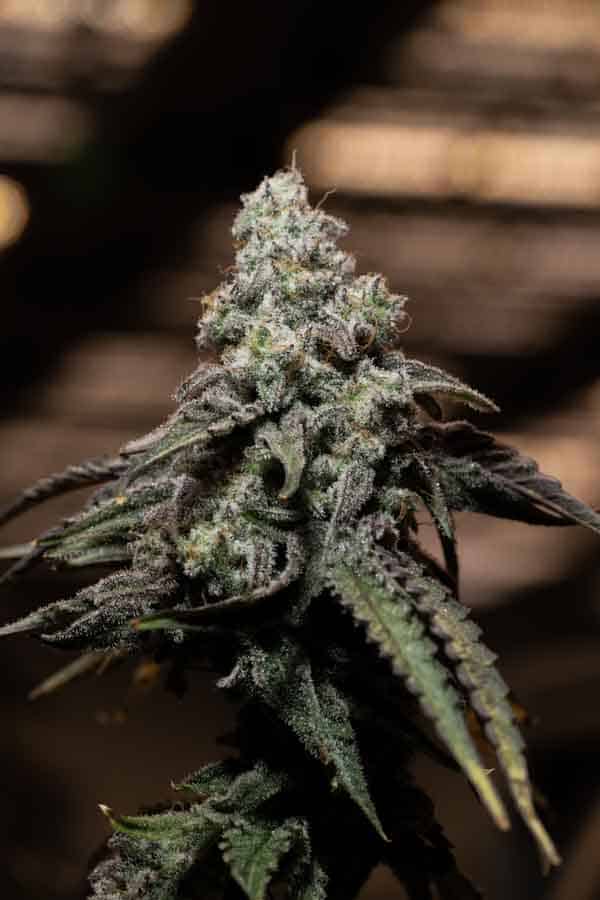

This simple philosophy applies well to those in the cannabis growing business: How does one get the highest amount of quality yield for the least amount of money?

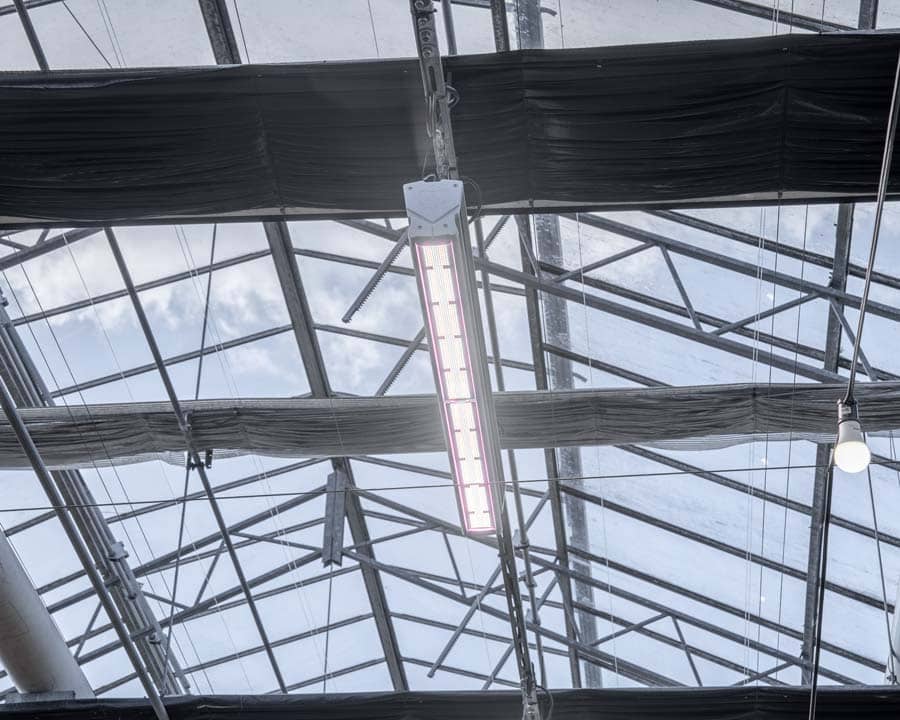

You can start by looking at lighting, which is one of the most significant expenditures for at-home growers and the large MSOs.

The problem with lighting

When my company began investigating how to make lighting more efficient with consistent results, we recognized that we had to address some of the “old-school” technologies disrupting a trove of inefficient, unsustainable, and harmful practices to deliver sustainable and high yield solutions.

The old LEDs were a short game solution – with lots of labor costs and massive fixture failure rates 5 to 8 years into their lifespan. HPS legacy systems were the same. Today, it’s about playing the long game and making investments that pay off.

Tech-savvy companies started to focus on sustainability and efficiency within horticulture and farming. Several lighting companies soon had solutions well-positioned to offer broad market adoption.

New lighting solutions

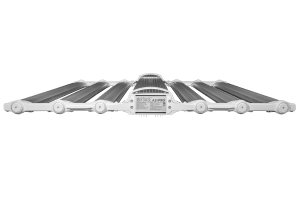

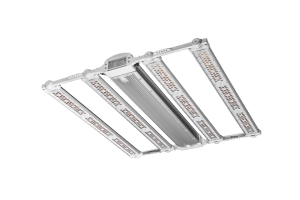

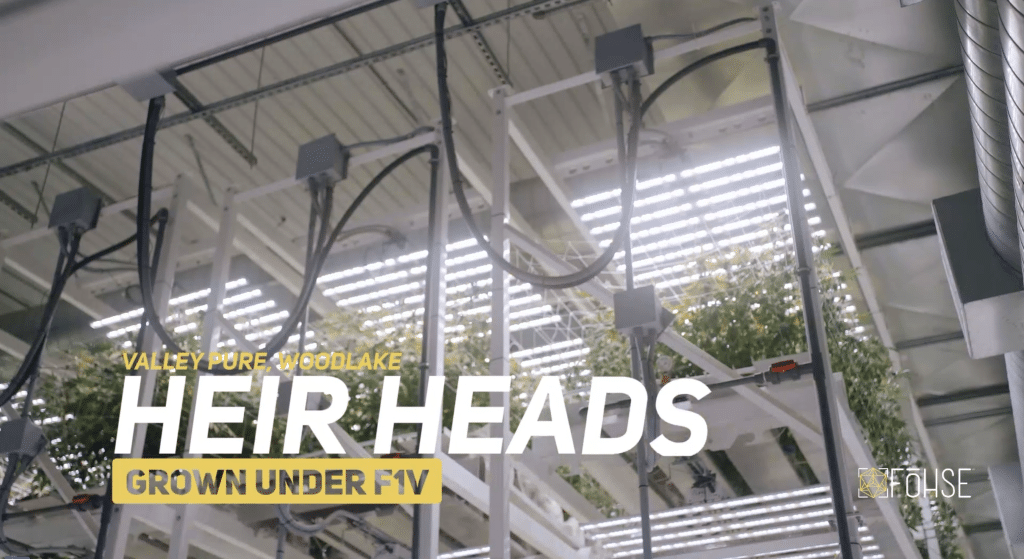

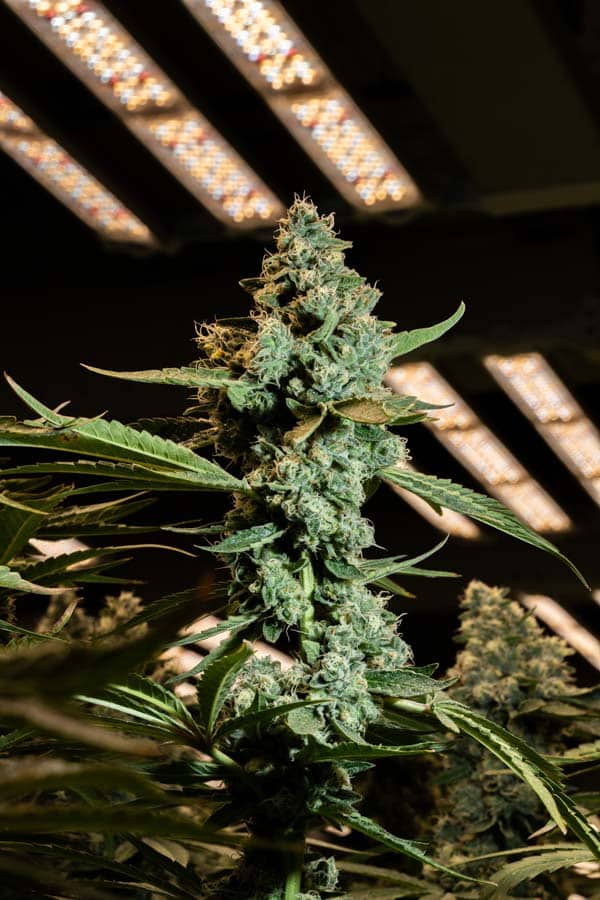

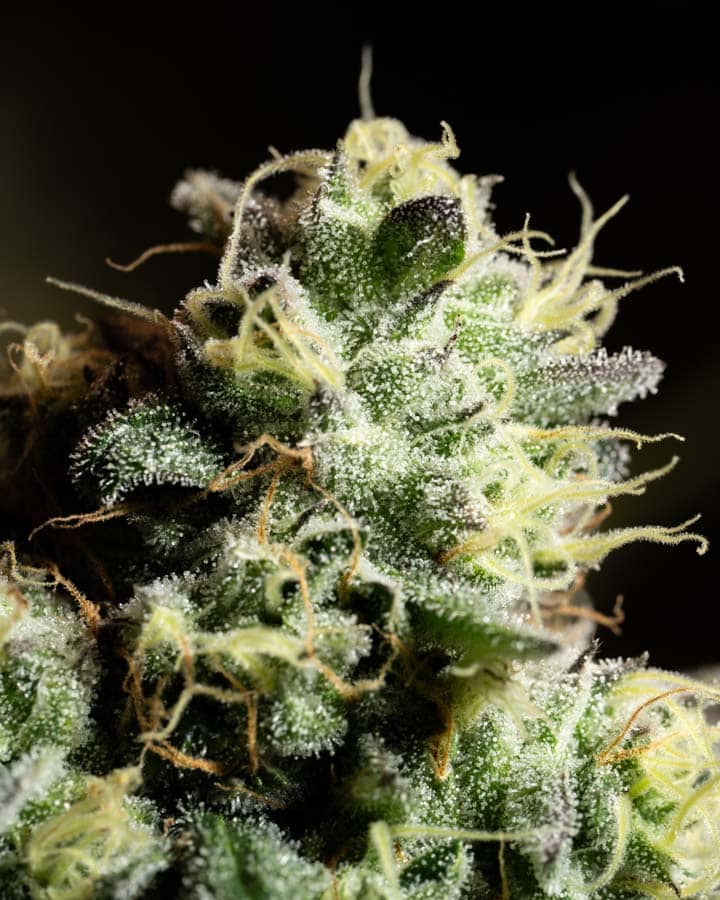

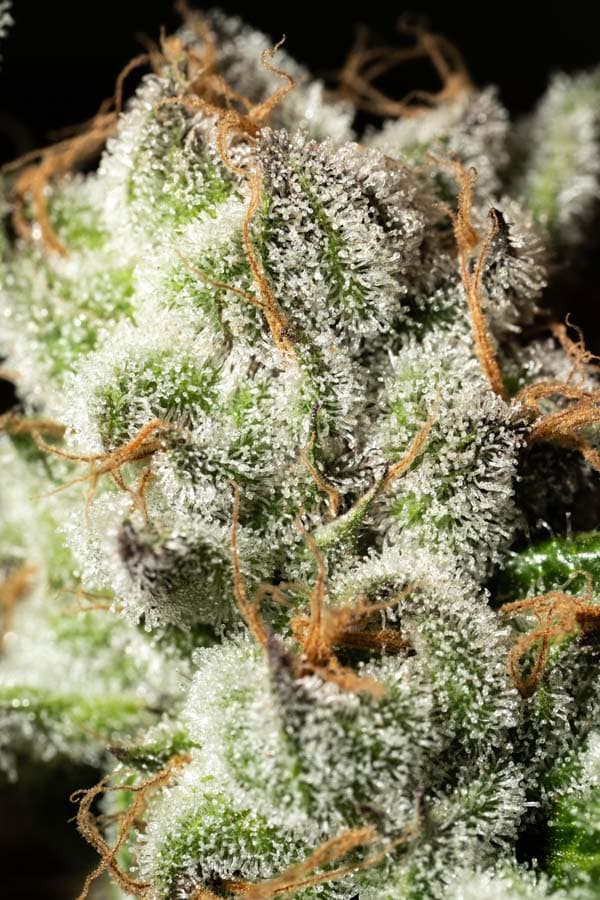

Effective lights in the horticulture space aim to deliver optimal photon energy to the target crop with as little energy and labor input as possible. Cannabis is a light-hungry plant and is especially gluttonous near the end of its crop cycle. Increasing light on the canopy comes down to manipulating three pillars of lighting design philosophy.

- Dial up the light levels by increasing the power of the fixture. This directly impacts utility expenditures.

- Bringing the fixture physically closer to the canopy. This is called ‘The Inverse Square Law,’ which states that the physical quantity of light at a point is inversely proportional to the square of the distance between that point and the light source. For example, if we increase the length by 2 feet, the light intensity decreases by a factor of 4 or 3 feet, and the light intensity decreases by a factor of 9. This directly impacts labor expenditures.

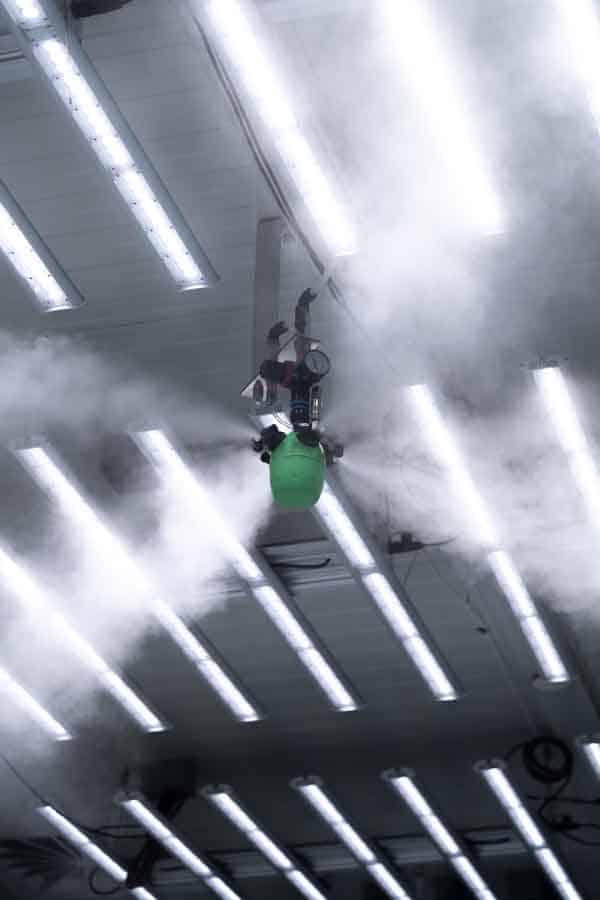

- While most lighting companies stop at the first two, there is a third way that considers the wasted light traveling in all directions through space. It’s called Lensing.

What is Lensing?

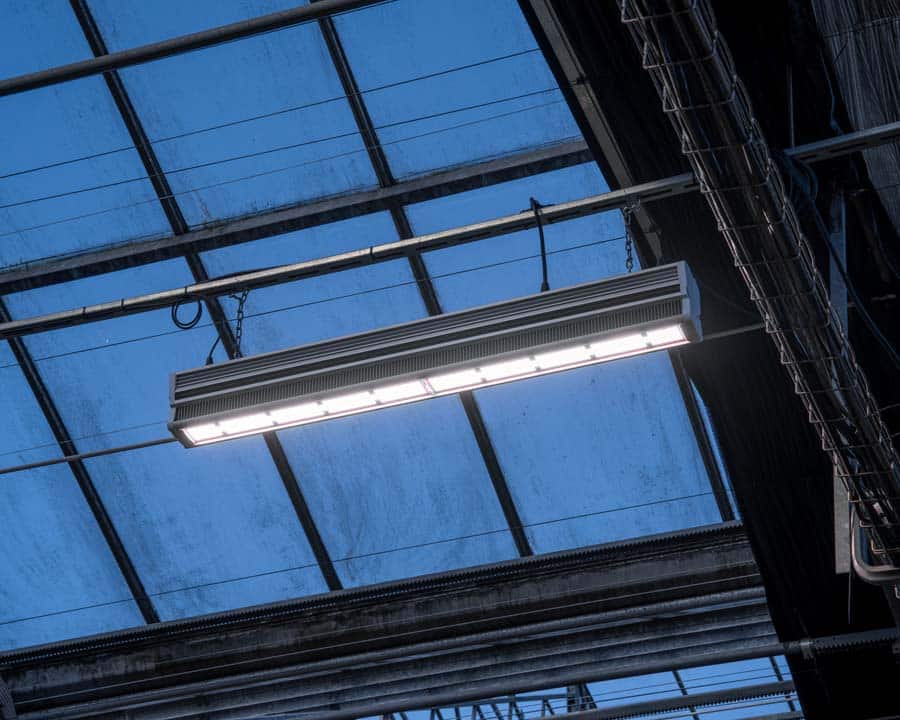

There are many ways we can capture and redirect light to a target destination o. Lensing is the most common way to achieve this in LED lighting. The Inverse Square Law still applies, but now we need a new equation that factors in all the redirected light. This additional 3rd variable in the equation is called the “beam angle.”

The primary goal of horticultural lighting engineers is to deliver light to your canopy as efficiently as possible by optimizing a system’s balance between these three variables and its total energy input. Therefore, to maximize lighting efficiency, consider the following:

Maximum output intensity

Low-output fixtures must be run at or near maximum output intensity at all times to maintain adequate photosynthetic photon flux density (PPFD) levels. Not only does this decrease the efficiency, it also reduces the fixture’s overall lifespan, and you’ll be replacing lights sooner than you think. A better choice would be a high-output fixture that can be run at a fraction of its maximum output intensity, thereby running more efficiently and maximizing its lifespan.

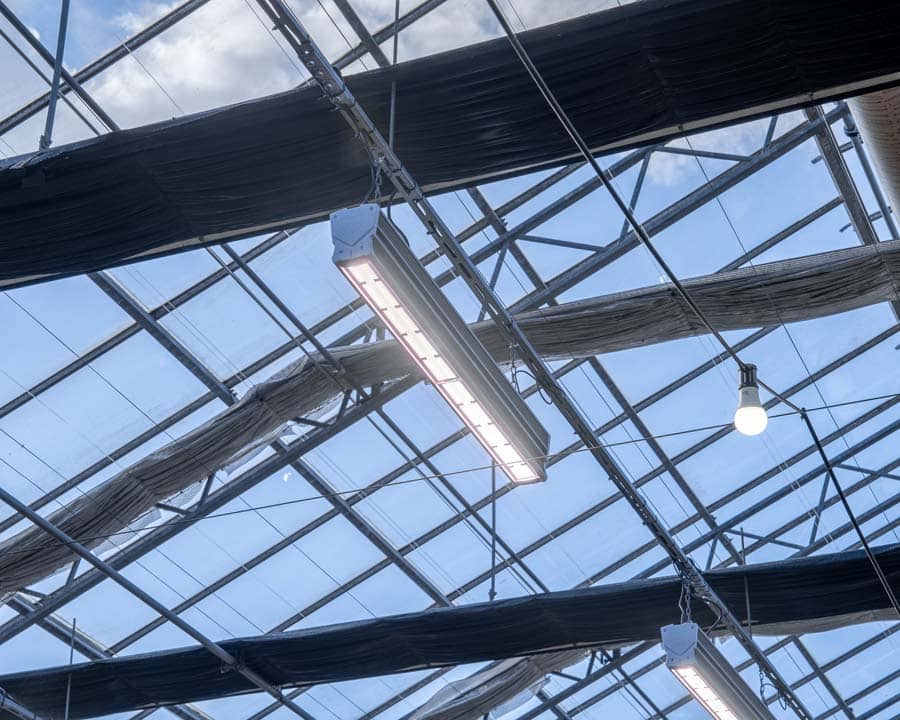

Hanging height

a. Low-output fixtures must be kept close to the canopy (6 – 8 inches) at all times to maintain adequate PPFD levels. While this may not be a problem for small hobby grow plots, it is a major issue for commercial facilities with hundreds or even thousands of lights. This practice of ‘chasing canopy’ becomes a costly labor nightmare at scale.

Lensing

Fixtures without Lensing must be dialed way up, keeping close to the canopy to counteract all the wasted light spilling outside the target zone This introduces additional energy and labor expenditures. The better choice is fixtures with Lensing that direct sunlight directly into the desired plot. Precision lensing components can drastically decrease energy expenses and eliminate the labor costs associated with ‘chasing canopy’.

Some fixtures come with Lensing, and some do not. How well one fixture delivers your target PPFD compared to another model depends on how well its engineers balanced the fixture and design variables such as energy inputs and photon output. Maximum output intensity, Lensing, and build quality.

With LED intensity, lights impact the industry by enabling productivity increases of 20-60 percent. When one is an entrepreneur, you sometimes have to play the long game. Look at expenditures upfront that provides profits for the future.

And remember Buffet’s other rule: “Price is what you pay. Value is what you get.”