Table of Contents:[hide]

Have you ever seen a beautiful cannabis crop in the grow, but the processed flower doesn’t look, smell, or feel like it did before harvesting cannabis? Maybe it is a shaved version of what it looked like on the plant, or the final nug sizes vary drastically due to inadequate cannabis bucking or curing techniques. Or, you grab your go-to flower at the dispensary, and its usual pungent smell is less than impressive this time around, possibly a sign that the cultivation facility’s cannabis care processes during post-harvest care can be dialed in for a better final product.

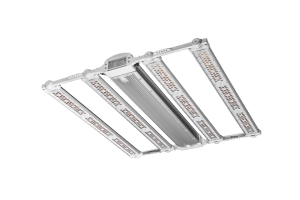

The operator’s focus is often on the cultivation phase of growing commercial cannabis. Choosing the right lights, the right cultivation SOPs, and the right cultivars are just three key parts of harvesting cannabis. Without these things, you’ll struggle to attain a high-quality product to send to your post-harvest team. However, without the right cannabis care, including cannabis bucking and cannabis drying processes post-harvest, high-performing LEDs and strong SOPs during cultivation also won’t matter. Your post-harvest care processes must also be dialed in for a premium final product, emphasizing the critical nature of each step, from cannabis care to curing.

An excess of automation, too many touch points by staff members, and improper SOPs during processing are three of the most common problems in post-harvest care operations, often neglecting the detailed attention required for proper cannabis drying and care. These issues can stagnate sales over time as consumers come to expect less-than-stellar quality from the brand’s final product.

There are a few things to consider before you overhaul or outfit your facility’s post-harvest care processes, including a thorough evaluation of your current cannabis bucking, cannabis drying, and overall care strategies.

Post-Harvest Processing

The post-harvest care crew, made up of many smaller teams, becomes responsible for the flower after harvesting cannabis. Post-harvest processing is equally as important as growing the plant itself. There are several touchpoints, SOPs, and areas of automation that can make or break your post-harvest care processes. This begins in the dry room.

Dry Room

This is the first place your flower will go after harvesting cannabis. Time, temperature, and humidity must be considered during the process.

You want to avoid major variances in temperature and humidity in your facility so the flower can dry evenly and without mold proliferation. Water activity is also important to consider. Water activity in cannabis is a ratio number comparing the vapor pressure of water in flowers versus the vapor pressure of the cannabis drying space. Your flower will stop drying when the water activity of the bud matches the relative humidity of the room.

Water activity is equal to equilibrium relative humidity divided by 100: (a w = ERH/100) where ERH is the equilibrium relative humidity (%). Relative humidity sensors of great variety are available for this purpose, including electronic hygrometers, dewpoint cells, psychrometers, and others. With a drying room set to 60% relative humidity, the buds will stop cannabis drying and exchanging moisture when the water activity level is 0.6.

The water activity level of your plants upon harvesting cannabis will be highly dependent on when your last irrigation event was prior to harvest. Plants receiving irrigation closer to harvesting cannabis will have higher water activity levels and need a longer cannabis drying time. Plants that were dried back longer prior to harvesting cannabis will have less total dry time needed before bucking.

How Long To Dry Cannabis After Harvest

The time that cannabis flower takes to dry depends on which cannabis drying method your facility uses. The three main methods are:

- Whole-Plant Hang Drying

- Partial Plant Hang Drying

- Wet-Trimmed Rack Drying

Whole-Plant

Whole-Plant

The more you break the plant apart, the faster the plant will dry. Genetics will also play a role in dry-down as the physical composition of different cultivars varies greatly from cultivar to cultivar. Harvesting cannabis using whole-plant hang drying takes the longest out of the three mentioned methods due to having the most biomass intact.

Also known as the “hippie hang,” whole-plant hang drying has been a go-to method for legacy and commercial operators for decades. This involves cutting each cannabis plant along the meristem away from the root zone and media. Tenured growers often opt for a whole-plant hang dry because of the results it produces.

The “snap test” is often used to determine when each cultivar is ready to be removed from the cannabis drying room for bucking. This involves physically snapping a small portion of the stem and listening for a dry, crisp snap sound. If the stem bends without breaking and/or is visibly green, it is likely not ready to stop drying.

A whole plant’s moisture content is higher than a portion of the plant, so the whole-plant hang is more forgiving than other drying methods because of the slow loss in moisture. This is an ideal method for new or confident post-harvest care teams.

Partial Plant Hang Drying

Smaller sections of the plant’s branches are used for the partial plant hang dry. Partial plants will dry faster than a whole-plant hang dry due to having less total biomass than an entire plant.

Wishbone-shaped branch cuts or 6”-8” branch cuttings are the most common sizes used during a partial plant hang dry, but partial plant sizing varies from grower to grower as well. Like the whole-plant hanging dry, utilizing the “snap test” helps determine when your flower is ready to be stored in the containers before trimming.

Facility operators should note that a faster cannabis drying time can be less forgiving, potentially leaving you with a flower that is too dry for the consumer to enjoy. Ensure your SOPs are tested and proven before opting for this method.

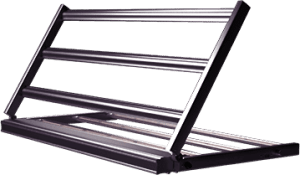

Drying Racks

Some cultivators dry the individual buds on mesh racks or plastic bakers racks. This method usually happens after plants have been harvested and processed by a bucking machine immediately after harvesting cannabis.

With the smallest window for perfection, this method of cannabis drying is not the most user-friendly or forgiving. Without proper drying standards for each cultivar, the flower will stop curing while they sit on the racks. The smell and taste of the bud will be negatively affected, subsequently turning buyers and consumers away.

Flat spots can also develop from the wet flower settling and drying on the racks, lowering the aesthetic appeal of your cannabis flower – something both consumers and retailers care about.

It is possible to make a marketable product with this method, but depending on your market, the quality may struggle to compete with others.

Cleanliness in the Drying Process

Beyond regulating your environmental setpoints in the cannabis drying room, cleanliness is the most important thing operators can control to ensure a high-quality product.

As plants dry down, material is prone to falling off. Sweep daily and after handling plants to ensure biomass on the post-harvest care floor doesn’t become a vessel for pathogens.

Ensuring filters are changed regularly. Not only will your utility bills increase if you fail to change them, but your air quality will also suffer.

Bucking

Cannabis flowers need to be removed from the stalk it grew on after harvesting cannabis, which is known as bucking. This process can be done a few different ways. Next to trimming, bucking is the most vulnerable touch point in your post-harvest care process. Your final product can be degraded if it’s not done correctly.

There are a few different ways to buck your flowers:

- Removal via scissors

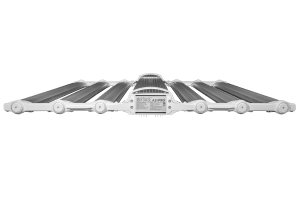

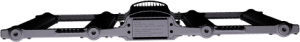

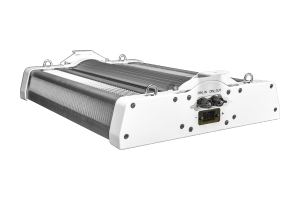

- Removal via bucking machines

Removing the flower with a machine is the safest way to buck flowers off of the stem. Machine bucking can work with dried plants or freshly harvested plants. As you feed the meristem into the bucking machine, it pulls the fiber through while leaving the remaining biomass from the plant outside of the machine.

This biomass like larf and leaves act as a cushion or barrier between the machine and flowers. This protects the integrity of the flower itself which is highly important for retaining potency and a high value appearance. Most operators choose this method because it’s more efficient, but it’s up to each operator to determine if this is the right move for their facility.

Removing flowers with scissors is another option. The biggest problems with this method are the inconsistencies from person to person and the time it takes to complete. Some can remove flowers with care while others may not, resulting in an inconsistent final product. This method can prove to cause more damage to the flowers, presenting the possibility for pathogen presence and degradation.

How and when operators choose to use automation is often overlooked can greatly affect their final product. In the case of bucking, it can prove to be highly beneficial as opposed to paying to staff a team. Operators should weigh the pros and cons of each method before implementing one in your facility.

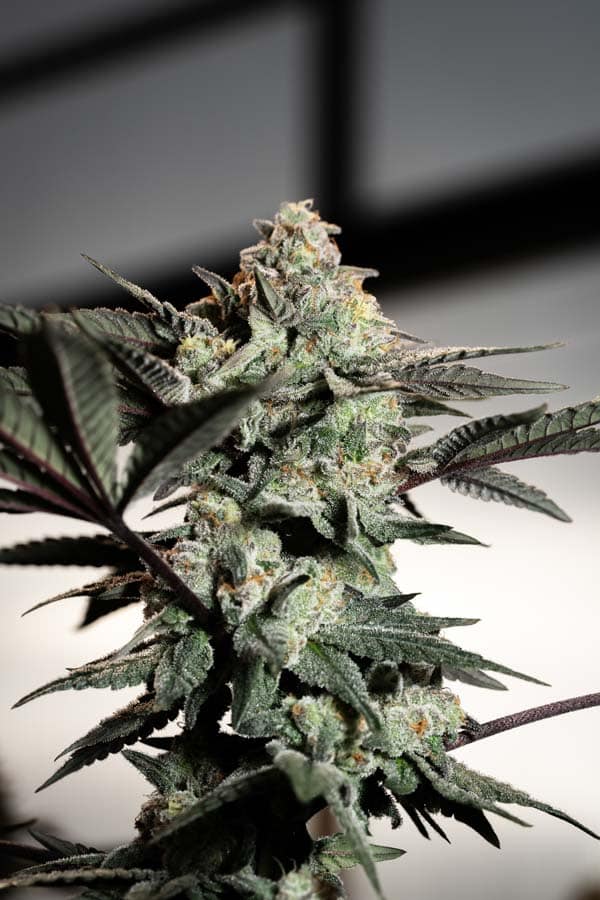

Trimming

Trimming is a key part of your product’s final look or bag appeal. A nicely-trimmed bud conveys a polished look and indicates the plant is healthy and well-cared for. It’s one of the final points of contact before the product leaves the cultivation facility and heads to the retailer. Proper post-harvest care ensures that trimming maintains both quality and visual appeal.

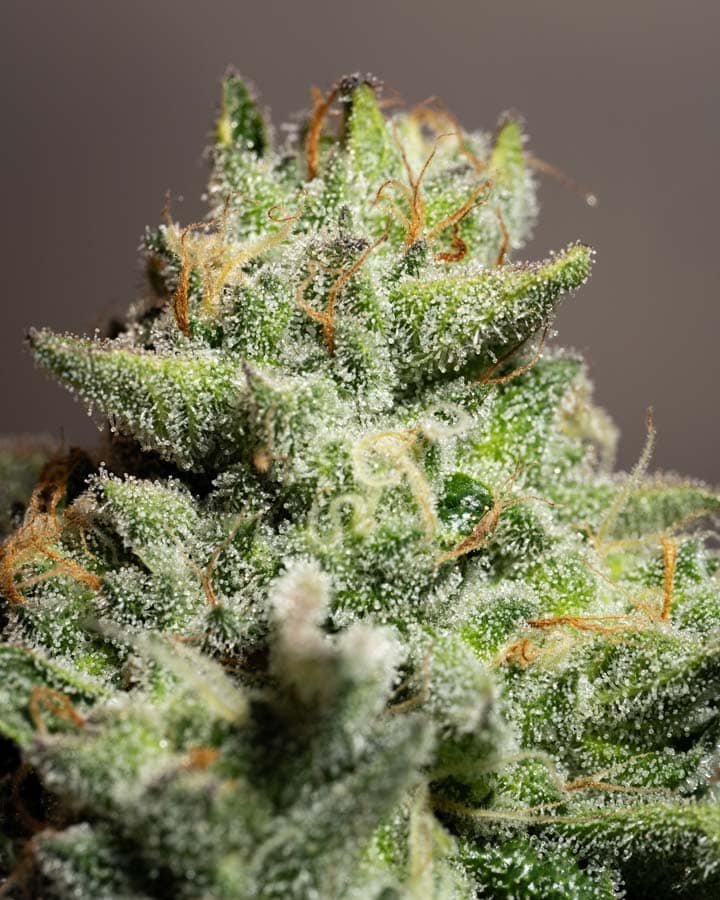

Business operators can choose between machines or hand-trimming their harvesting cannabis flower. Hand-trimming cannabis flowers can preserve your flower’s fragile trichomes for the frostiest flower possible. This is an ideal solution for craft or luxury cannabis brands who are aiming for a curated consumer experience, but it’s not always the most efficient.

Automated trimming machines can reduce the need for a trim team, which is an ideal solution for those operations with small staffing budgets. It’s also effective for large-scale harvesting cannabis operations that need to move large quantities of flowers to meet demand.

However, these machines can be rough and you’re often losing trichomes, reducing the flower’s potency. It also changes the final look, sometimes shaving the flower too deeply – erasing the unique shape and size of the individual variety.

It’s up to the operators to weigh the pros and cons of each method and decide what works best for them. Regardless of the route you choose, make sure your standard operating procedures are tested and consistently reviewed for improvements.

Packaging and Cannabis Care

Some operators treat packaging and the care of cannabis like an afterthought, but it’s an important part of the post-harvest care process that could make or break your final results. Different packaging materials influence the preservation and moisture content of cannabis. Seasonal variances and changing environmental conditions can affect materials differently.

Cannabis drying, cannabis bucking, and storage under uncontrolled conditions like high humidity can lead to fungal infections. Some mycotoxins like aflatoxins and ochratoxins require oxygen to grow. Therefore, eliminating or reducing the oxygen can slow the fungal growth during cannabis drying and storage. As well as poor drying and storing under humid conditions, can promote microbial growth and toxins like aflatoxin and mycotoxin-producing strains of Aspergillus, as well as powdery mildew and Botrytis.

In order to preserve the shelf life of your final product, it’s imperative to understand the post-harvest care process and how cannabis degrades. The presence of heat, light, and oxygen are the main factors that degrade cannabis flowers. One March 2022 study, for example, found that, “Packaging material should not be plastic bags, as they encourage mold growth–instead use only a glass jar for cannabis drying and curing.” Properly sealed, dark glass jars reflect heat, keep oxygen out, and are well insulated against the environment.

If you thought you were in the clear at the B2B point of sale, think again! After packaging your final product, it will have to endure the environmental conditions of each season en route to and at the dispensary.

Every localized environment differs in seasonal temperatures and humidities. States like Nevada, Arizona, New Mexico, Utah, and Colorado have to consider how they will keep their products “wet” enough due to low average relative humidities. These states can add moisture regulating packs to their storage containers in an attempt to preserve the moisture content.

States like Alaska, Florida, Louisiana, Mississippi and Michigan have to consider how their product may increase in moisture when it leaves their hands. Sending product out at a slightly decreased moisture content can help account for this variance. Accounting for these responses to seasonal conditions can help operators deliver a safe and high quality product year-round.

With a higher frequency of automated systems or touch points by staff members during the post-harvest process, you will see more degradation to your final product. After investing into the growth of your crop, it’s imperative to consider these post harvest processes and implement strategies that protect their ROI.

Get a Free Light Plan

Setting yourself up for post-harvest care success begins in the grow. Proper planning is imperative to get your product, including cannabis care, ready for post-harvest care crews, which can impact how it’s processed, including harvesting cannabis, cannabis bucking, and cannabis drying. Efficient, high-performing materials and equipment are necessary parts of your cultivation operation. Elevate your post-harvest care process with FOHSE LEDs and request your free lighting plan today.

![Client [HIGH]💡 | Terp Mansion | A3i](https://resources.fohse.com/wp-content/uploads/2024/05/Terp-Mansion-Best-Of-2.8.24-WEB-39.jpg)

![Client [HIGH]💡 | Terp Mansion](https://resources.fohse.com/wp-content/uploads/2024/05/Terp-Mansion-Best-Of-2.8.24-WEB-45.jpg)