Kevin Kuethe visits Welcome To The Future podcast for a dose of cultivation. In the second installment, Kuethe revisits the early days of his career in cannabis, his partnership with Fohse, and his transition into becoming the VP of Cultivation at Lume Cannabis where he designed, and operates 250,000 sq ft of Cultivation, 75 acres of outdoor, and a processing lab.

Tune in Friday, April 1, live at 3pm ET/12pm PT for Growin w/ MrSoul featuring Rick “MrSoul” Campanella

*Disclaimer these were transcribed from an audio file. There may be dictation errors and misspellings due to direct translation. Dictation Error(s) - The dictator himself / herself makes a dictation time error which simply gets transcribed verbatim.

Speaker (FOHSE)

Yo, yo, yo, guys, what’s up? We’re back with another episode of Welcome to the future. This episode is very, very special. We have folks as president and CEO and CEO and president Bret Stevens and Ben Arnet are here with us. And we also have Mr. Kevin Kuethe, the VP of cultivation of lume cannabis. He’s sitting down with us for today’s episode, we’re going to chat, we’re gonna get into his journey. Why he chose cannabis from Michigan to Vegas, all of that good stuff. And um, yeah. Kevin, welcome. It’s a pleasure to have you here. Yeah. Good to have you, brother. Absolutely. Is this your first podcast?

Speaker (Kevin Kuethe)

When was your first official one, um, you know, we’ve done a ton of different media stuff. You know, over the past decade or so from facility to facility, I’ve done a few podcasts, you know,

but mostly we’re doing articles, have a lot of magazine articles, and a lot of local news presence, especially in and around where our facilities are. In Michigan, we’ve got, you know, over 30, retails, they’re now operational, and then several different cultivation sites. And we play a pretty big role in the community that we’re in donating. And, you know, not only money, but time volunteering. So we’d like to make a positive impact everywhere. And that’s really gotten us kind of intertwined in the cities we’re in.

Speaker (FOHSE)

So what’s been one of the driving factors in the cities that you’ve selected to really start business in?

Speaker (Kevin Kuethe)

Well, the cultivation facility, which is what I’m responsible for, is right in the center of Michigan, we’ve got a 250,000 square foot indoor facility there. It’s in a town of about 1400 people. So it’s a small, small population, I’ve got 300 employees, they’re just at the indoor facility. And so we have people, as you can imagine traveling from all over to work there. It’s a great work environment. I mean, we just won 2022 best cannabis companies to work for both for cultivation and for the retail side. And then mg magazine just gave us best cannabis company to work for, as well for 2022. So we’re celebrating that stuff. And people have worked kind of spread people traveled to work for us, and with us, and the growing opportunities they’ve seen, I think, have been pretty outrageous. And, you know, with growth comes opportunity fears for a lot of people. So it’s, it’s been good man. But But selecting the areas, I mean, we selected that area in the center of Michigan, because a we knew we were going to have a big footprint there all over the state, we want to have good distribution. So Senator, the state’s the best spot, right, so we have great distribution there. We also had one of our founders had a big chunk of land there and own some buildings. So that’s where we actually put up the first phase of the indoor facility. Because he had, you know, good ties and property there.

Speaker (FOHSE)

Gotcha. And then for those that may not know what specific area of Michigan you are referring to you say right in the center, but would you mind the name of this specific area?

Speaker (Kevin Kuethe)

Yeah, absolutely. It’s a little town called Everett, Michigan. It’s just north of Grand Rapids about an hour and 15 minutes or so.

Speaker (FOHSE)

Awesome. So how did you meet these two guys here? How did this all come together? How did the meeting of the worlds happen?

Speaker (Kevin Kuethe)

Well, before Lume I was Chief Operating Officer for a publicly traded cannabis company called CB sciences GBL X and OTC ticker, a pink sheet stock, penny stock. And I had built a facility here in Vegas, unlike any other I had done before, I had a larger budget. And it was a biopharmaceutical company where they wanted to produce medications for ailments from specific combinations of minor cannabinoids and terpenes. And, you know, I loved the opportunity. And so when we built the facility I chose to go with, you know, making it much more of a cleanroom style, because of our company’s mission. So we built it out of pharmaceutical grade cleanrooms, a company called Porter fab. You know, it’s basically fiber reinforced plastic, it’s non porous, and it’s easy to clean. And we use really efficient controlled natural gas for cooling, you know, we’re basically running off total four cylinder engines outside of the pump, glycol tour, air handling units, and then we would dehumidifier and cool with those extremely efficient. And I was running all HPs because my entire life had been running HPS lights. But here was this magnificent facility running all these PS which to me, I already knew that the future of lighting was going to be developing and that was going to be one of the first things that changed in cannabis. Because of how ridiculous the old school lighting really is. The technology is 50 years old and it produces an insane amount of heat and we’re all trying to be efficient here and save the planet. They make no sense. You build this massive mechanical infrastructure to try to handle the cooling behind these heaters that you’re putting in your room. But you know, so I knew that was going to change. So at GB I started I had the opportunity to run on a real test, and to me, that’s one of the most important things about running a commercial cultivation making decisions is you got to make data driven decisions, and you have to be able to collect data correctly, which I’ve learned the hard way before and collecting the collecting it the right way, is having spaces that are the exact same that you know, not only mechanically, but everything you’re running a real control study, and the data you’re collecting, and not only collect it, but how to aggregate it and more importantly, how to read that data. And then to make good decisions based on that. So a GB I knew we had an opportunity to do a really good test there, because of the uniformity of the rooms and mechanical infrastructure, everything was brand new. And it was really state of the art, you know, for the time, we mixed all of our own nutrients from scratch, so I could, I could control levels. And you know, we’re doing massive testing runoff and everything. So I had a really good control. And I started to test LED lights. When I went through, I went through at that point in time, you know, over 10 all the way through flower, you know, because I was in GB for years. We went all the way through flower. And what I noticed with every light is that, you know, with our growth techniques and the mechanical capabilities of the room, we had the ability to start getting really good looking buds and some large dead spots. But they were all primarily at the top of the canopy. And the yield just wasn’t touching what I was really nailing with the HPS. And I was able to get over four pounds, a light of dried, trimmed, cured, beautiful flower. And, I needed something that I could swap out and at least get what I was getting with HBS. If I couldn’t at least do that, then I wasn’t going to switch no matter how good the technology was. I wasn’t willing to give up the yield. Because you know, he’ll drive. They drive a successful company. Absolutely. Sure. So. So I, you know, started running through all these lights. And I had an employee at the time and said, hey, you know, I have a couple of friends that have just started LED company, and it’s great technology. And honestly, I want to just say no thanks, man. But But, but I’d already been tested, somebody let’s say he had been, he’d kept bugging me about it. And I said, Sure. All right, fine. Set up a meeting. So they came in and it was Ben and Brett. And we talked about it had a great meeting I told him I’d been running through LED lights and testing and run them all through flower I had a bunch of in the facility at the time that came and and I was like I didn’t have much hope I told him was like enough. Just so you guys know if it doesn’t work, I’m not gonna keep running. I’m gonna take it down and give it back. If you guys don’t pick it up. I’m gonna put it outside.

Speaker (FOHSE)

that time to write when you’re testing lights, that’s the other thing. Literally, you’re going through a lot of products.

Speaker (Kevin Kuethe)

You go through products, you know, it’s not that it’s unsellable. But it’s just not ideal, where you’re trying to get dollars, you know, or it makes sense in business, you have to be able to produce commercially at a good rate and have a low cost to produce and regress.

Speaker (FOHSE)

We don’t want to do the one thing with testing and anything I think is you don’t want to take the risk of regressing when you test you want to test, get the information and keep moving forward without much error or loss in between.

Speaker (Kevin Kuethe)

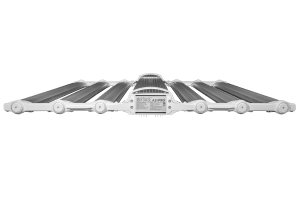

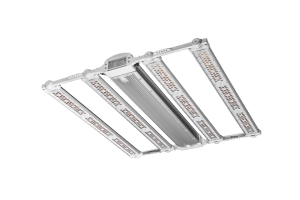

Exactly. Yeah, exactly. So we put up a couple of the full slides, I think I put up one first around a run through I was like wow, it actually maybe it’s across lighting or something. So I got another one put up. And we were hitting about the same and in some circumstances better yield. And to me, that was enough. I had I had I had done it. And to me, I also knew that I was testing one of the first lights. And so I knew it was gonna give me a leg up in the competition, you know? And so I started to kind of get excited and it was like a secret. But you know, fast forward years later, we’ve got 250,000 square feet up and it’s all full slice. We use the API in the flour and we just absolutely crush it now. You know we’ve we’re celebrating the facilities recently. Growers get paid on a bonus cycles and the bonus goes all the way up to over four pounds likes we regularly hit that but they’ve been hitting five and a half recently and you can’t qualify that five on

In layman’s terms it’s easiest for people to see there’s a million different metrics grants for foot graspers. Well, I know, how many lights do you have in the room and I use five foot tables. That flower is that when that’s finished trimmed, cured flower we call it flower popcorn it’s everything that I can sell that’s trimmed. No this is what I’m you know, because we have a retail store we’re vertically integrated. So this is what we’re , this is our bread and butter. So this is ready to go. Yeah. But you know, we been able to? Well, we’ve learned a lot, your lights actually made us learn a lot. Because it’s starts to trigger the thought process of okay, well, we know that plants thrive on light energy, and they want to grow more. But if you increase light, and because we’re all stuck in this HPs world of, you know, this, this many lumens, or this one, this is the, this is the PPFD, it just comes standard. And, you know, you end up starting to think about in your head, you start to think about, well, if we increase the light intensity, the plants going to want to do more, you know, there’s, which means we need to give it more nutrient, otherwise, it’s going to lack in nutrient levels, and it’s probably going to drink more water, which is what we started to see, you know, when we’re a very first room we put up with just the eighth rise, we started started watering almost twice as much, and for nutrients, you know, almost doubling and but so as soon as the growth and it, you know, it’s you learn a lot like I said, you go through that, that process in your head and starting to tweak it and dial it and test around. Okay, how much nutrient can it actually thrive on? And what’s you know, what’s happening with the plant, it’s pulling up water and transpiring moisture right through the storm releasing little pockets of evapotranspiration, right, these little humidity pockets into the room. And if you have the ability to remove all of that and continue its metabolism, puppets metabolism, along with the combination of light energy, giving it everything it needs on a nutrient level, the plant could do outrageous things, you know, outrageous things, a lot of people are stuck in the two pounds per light, mental space, we’re like, really, you know, yes, you can make money off that man with that much. And sure, that’s been standard for a long time. But that’s not the limit of the plant by any means, you know?

Speaker (FOHSE)

And so transitioning to where you are today in this current phase, with loom, what keeps you going and finding ways to reinvent the brand? Obviously, with cannabis, it can get old because it’s cannabis. Right? But how do you find ways to keep being innovative and then growing the brand?

Speaker (Kevin Kuethe)

Well, you know, growing the brand, it’s kind of left up to the marketing department. We’ve got an outrageous marketing team here, we’ve got 1200 employees now. So we have a serious department for everything we need. But our, for me, what changes and continues continues to keep me interested in what drives success is optimizing. And always trying to optimize to optimize and never stop, at a certain point saying, Oh, that’s okay, that’s good enough, you know, that’ll do it, there’s always waste. You know, like I say, we’ve with all my growers, if they want to try something, we’ll test it, and we’ll collect the data. And we don’t, you know, if it doesn’t work, we have to test it again. But we will do, we will test everything if we all think it’s a good idea. And we brainstorm and go through stuff all the time, we’re talking to, you know, people from universities, and PhDs and going out of our way to, to learn as much as we possibly can about the science behind the plant, and doing what we’re doing on a commercial scale. Because what a lot of people don’t realize is commercial cannabis hasn’t been around legally, for a long time. There’s not textbooks on it. And guess what, it’s a plant, it’s, you know, it’ll grow, there’s a million different ways to grow it. And everybody can say, this is great. But I think diving deep into the actual science of it, and you know, doing your own experiments and understanding what’s happening with the plant, is really what’s exciting and fun. We also have a ton of new projects that we’re always expanding, we’re always building, you know, we have 75 acres of outdoor space that we’ve got big. We have nine greenhouses now. And we have a massive drying facility out there as well. Pretty, pretty cool, new dried technology. But the new projects keep it really exciting, and always trying to be competitive on a commercial scale in the industry is motivating. For sure.

Speaker (FOHSE)

Yeah, one experiment that we’re really excited about going back to it’s gonna hit on two things that you mentioned. With increased, like needing increased feeding with Kevin’s facility. I mean, he’s downplayed how sophisticated it is. Really. I mean, he’s, he feeds basically on VPD schedules. So when he’s talking about transpiration rates, he’s seeing the transpiration rates, or you saw it go from HPs however, many gallons per room to an increase of transpiration rates and a direct correlation to increase yields and quality everything else because of, you know, transpiration rates, like you said, goes right back to the energy that’s going into the planet. But one of the experiments he’s running is different feeding schedules, or EC levels of nutrients and feeding based on increasing light levels. And I know he just started that one. And we’re just starting to get some data back from that. And it’s super exciting to see, you know, where that sweet spot is. And it’s not really where the entire industry thought it was. So it’s, it’d be fun to touch.

Speaker (Kevin Kuethe)

Yeah, man. Absolutely. I’m excited about that. Well, first of all, we are so lucky to have our own r&d room. Of course, we outfitted it with the API’s but we have up to 12 light rooms for one more reminder per table. And well, there’s just so much control we have. We can do their digital, I can change the light intensity, you know, to the percentage point and I can change the spectrum on them and I can do a lot of different things. There’s a lot you can do, they’re versatile.

So we have an r&d room where we’re running the test with nutrients, you know, we do fino hunting and stuff like that. But we also do a lot of controlled tests or running nutrient tests. Now we’re increasing the EC, and the light intensity, right at different stages and just trying to find where the maximum and the and that perfect point is to drive the plant as much as possible, you know, have a habit of doing what it’s genetically capable of doing. But it’s a lot of fun. We’re three weeks in right now, we basically ran a control study with our typical EC and then increased it on each table and then played with a light intensity as well. So we’ll see how they end up but we’re already starting to notice a faster growth rate on plants with a higher EC level and higher light intensity earlier on. You want to talk about those easy levels are not really not yet.

Speaker (FOHSE)

Now there’s the dual sided question here. I mean, for best and brand on our side with LED lighting, what are two successful factors that you guys like to see from cultivators when they use your products?

Speaker (FOHSE)

Well, one, you know, depends on what level of grower they have. But for the most part, I mean, we don’t do pushy sales tactics, we don’t do crazy marketing stunts, what we’d like to actually do is just say, let the plants do the talking. If they need to, you know, have assistance from our horticultural team, or our engineers, we’d like to get them on site right away. The reason we have so many successful clients, I mean, Kevin doesn’t really need some of those services. But some people do. And when you have that to, you know, fly couple guys up, maybe train their team, whether it be they want to know, you know, what EC levels are on environmental controls crops hearing, or we had to bring our engineers that look at their infrastructure to see if they need, you know, they don’t have enough dehumidification, they have too much H back, we can look at a lot of stuff and work through stuff with their team to increase their success. Because we’re not just letting guys first and foremost, you know, Fohse is an engineering firm. So definitely take advantage of that when you become a client or you know, more so a partner with us. But the big thing is just seeing the success, we like to look at what you’ve done before. Look at the metrics yields COAs. And let’s see what we can do from there. Let’s see if we can find value. Yeah, where can we provide value with our lighting system? Is it going to be increased yields of terpene levels cannabinoids, what are we growing? For? What systems are going on? Are you just trying to reduce your costs or we have no wattage restriction we’re trying to attack, let us know what we can do. We’ll build custom lights, Custom spectrums, whatever you need. I mean, we will build lights to R&D, if you need them. If you want to try something crazy, we’ve got like at least three for this guy.

Speaker (FOHSE)

That goes back to the comment that we say here at first with our successes, your success. And I mean, he kind of gave that as an example there with properly assessing what the client needed, where they currently were with their flour, where they currently were with their facility and how we could improve and make it better not just for us to benefit, but for the clients also benefit for the long term, you know, for the partnership, you know, that’s the long term goal is to really build something sustainable. What about for you know?

Speaker (Kevin Kuethe)

I mean, the technology is too new to not do that. Yeah. That’s why you can’t just Yeah, I mean, we’re in a phase of the industry where science and experimenting is what we’re supposed to be doing, you know, and there’s no right or wrong way until you just do it. Right. And you’re proven it, you know, you’re you’re proving it.

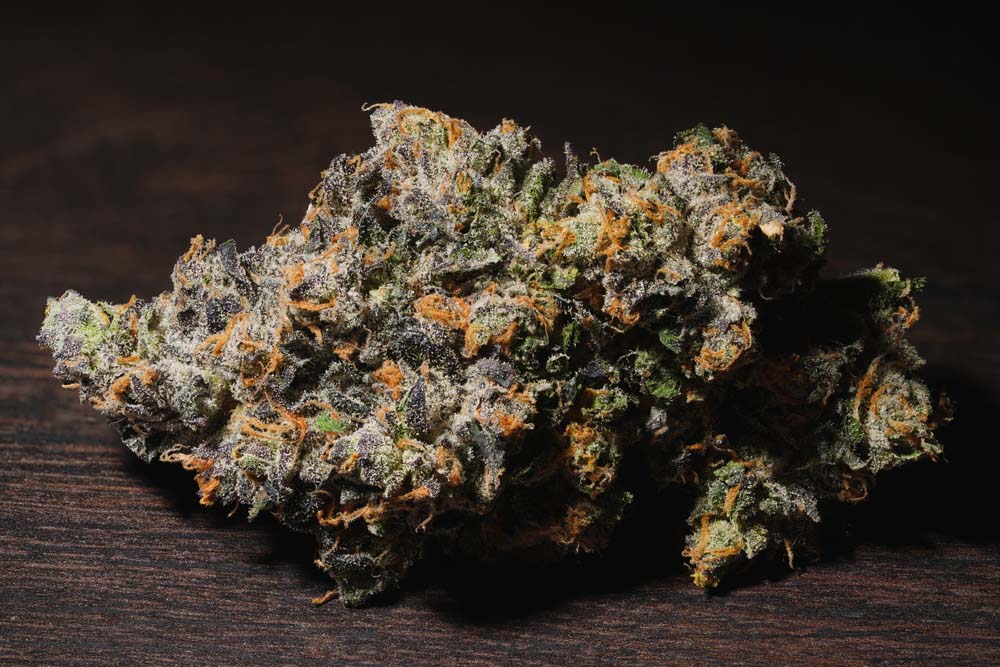

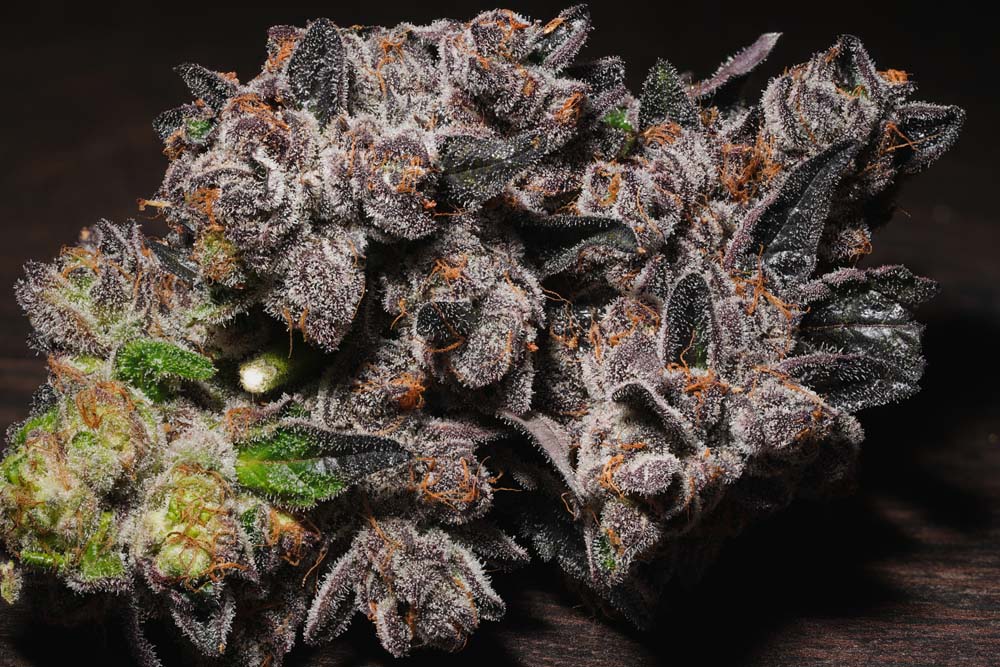

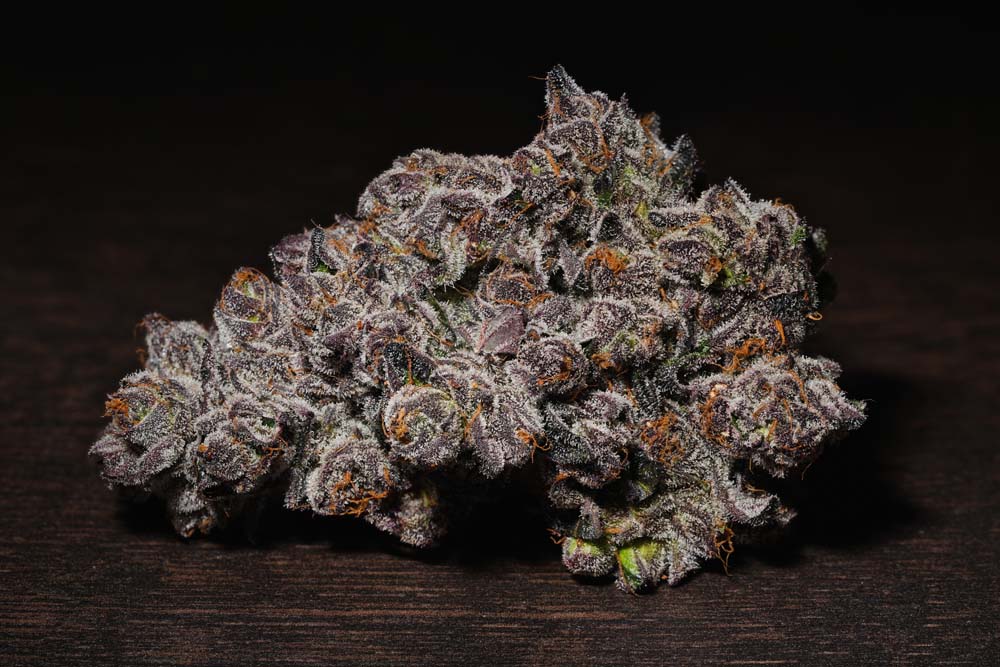

And so yeah, that’s, that’s the biggest thing. And yeah, what I look for immediately is, of course, what every commercial grower wants is a bigger yield, higher choir quality plant, which means, you know, higher terpene levels and bigger, better bag appeal and everything like that. It’s just all this, let’s talk about that for a second.

Speaker (FOHSE)

So you’re saying you’re getting five and a half a light five and a half pounds?

Speaker (Kevin Kuethe)

We’ve had to date but we’re regularly hitting over five pounds a light.

Speaker (FOHSE)

What does that look like when you’re testing? What are you doing for a percentage?

Speaker (Kevin Kuethe)

We have six strains in the 30s, you know, and that’s total THC. So growing big plants doesn’t mean growing less quality? No. I mean, I would disagree with that. I know that’s a thought process out there. That’s a belief out there. But the reality is, it doesn’t make sense. Well think about all the crosses of cannabis, they got how many strains there really are, there’s bound to be some that are heavy yielders that look great. And that tests over 30 that are really that are really potent. I know we have six at our facility right now that tests over 30% for total THC, which by the way is an algorithm on how to get there from your THC A which is the actual number of THC in there. And then our Total Connect cannabinoids are, you know, often in the 40 percentile if not the upper 30s You know, and for me, those six genetics are huge yielders, those are the ones that are regularly in that five pound category. So I know that there’s smaller yielding strains that have good flowers of course, but I just don’t want to grow them if I don’t have to, you know.

Speaker (FOHSE)

So let’s break down this part there too. Let’s break down that misconception. Obviously, we know why because people think that their lights, you know, bigger products are better flopping. Why was farther back than that? Honestly?

Speaker (Kevin Kuethe)

I think it goes farther back than I mean, first, yes, not everybody has the ability to have an incredible mechanical infrastructure and yadda, yadda yadda. But and typically, most of genetics today are a blend of so many different breeds that have gotten to the point of where it is. And it’s mutated and yada, yada. And it’s usually not a really strong, resilient tons of landrace, you know, in it, where it’s where it’s a big, strong, potent plant, you know, typically.

So I think that because it’s been so regular and so common. In the past, you’ve got to remember that 1015 years ago, everybody’s grown in their basement or in a small garage, or maybe an illegal warehouse with not that many lights, they’re not running crews and crews of people, is it at least not not that many people were.

And so you have to take all of that and consider it into consideration as well. I think if this had been commercialized here for 100 years, oh, yeah, they would have maximize this long time ago, I just look at it like, like a farmer, look how farmers look at everything. Anytime a farmer, a commercial farmer gets his hands on something, or is trying to grow a crop, I promise you and I’m talking to a big commercial farmer who visited many, many of these guys, they will find the absolute cheapest way to produce that product on a commercial scale that you it’s a margin game period. And nobody can beat him no matter what they have to automate what genetics they use, but that is really with that in mind, and having that as your competition, it’ll drive the success and larger yields and large, larger yielding genetics that are more potent, higher quality. Yeah, like I said, our best genetics are heavy shoulders and are also our highest testers.

Speaker (FOHSE)

When you also gotta remember to, I mean, everyone has had to grow with HPS, the most PPFD you’re gonna get to your plant is what 1000 1100 before he becomes an issue, low powered LEDs, you’re right in that same ballpark. So I mean, for since cannabis has been legal, that’s kind of what you’re dealing with is 800 to 1200, maybe unless you’re slamming lights down. So there’s definitely been technology built for a crop like this in a commercial setting where we were like, Hey, if you want 1200 for that plant, and you want 2000, for that plant, we got you covered, there’s not really been a system that’s been able to do that. So I mean, that’s why I think it’s new and you have to have guys like Kevin who are willing to go and you know, push the limits and kind of see what the genetics actually want to do. And, you know, we’re finding out it’s, we’re barely touched the, you know, touch surface of where we can take it for sure.

Speaker (Kevin Kuethe)

And also hold out for the good ones, you know, if you find a good one, it’s not enough to just accept it, you know, a lot of people but if they take time to grow, it’s all it takes a lot of time and effort, energy and money. And those things drive your decisions. Also, you know, so a lot of factors, man, but that’s where my head has been, uh, since I’ve been in the commercial cannabis industry. You know, it’s over a decade now looking at all the genetics I’ve had, and, and realizing the diversity of, of genetics and and what’s capable, you know, what they’re capable of. So, I hold up for the good ones.

Speaker (FOHSE)

One thing that I’ve noticed that’s really uncommon that both of you two have in common between both parties is patience, and being able to kind of take your time build something, if it doesn’t work, go back to the drawing board, you know, in a couple conversations we had earlier this week, you know, when they were developing the lights, they went back to the workshop, like, Alright, we’re going back and test something new. And like you said, is taking the time to test, get the data, study it make the changes that need to be made? And then you know, get the results that you want?

Speaker (Kevin Kuethe)

Yeah, that’s a luxury though. It really is. Because most places most of the companies have been a part of, especially before this was we got to make money, because it’s all privately funded. Banks are involved. I mean, debt has a big part of your decision making, you know, plays a big role.

Speaker (FOHSE)

So speaking of that decision making really quick, what makes you choose quality over the ones that don’t make that right decision that you just referenced?

Speaker (Kevin Kuethe)

Well, as far as genetics go, you know, they have to play, they’re really just three things. For me, some people put it in four categories, I like to play three, number one, it has to be a good test result. And whether that’s at an outrageous terpene profile, a really cool minor cannabinoid bland or it’s really high THC, it’s just gotta have a good test result. Number two is it’s got to have a good nose flavor, smoke, you know, that section of the Planet X will consumption has to be on point, whether it’s a unique terpene profile, whether it’s a unique flavor makes your mouth water, it looks outrageous, you know, something like that. And then And then the last one, which to me is one of the most important things is yield. And making sure it’s in that yield category where I can a there’s a lot of back end stuff that goes into a genetic decision making as well especially on a commercial scale, because you have to think down the line. We’re going to dry this plant. How well does this plant dry? What’s the stock thickness, what’s the moisture content? What’s that? How long is that enzymatic process going to take? So you know this chlorophyll gonna leave easily is going to take longer. What’s my process? And then on the trim side, I also have labor on the trim side, I gotta remember that I’m paying for that. How much is that buddy’s gonna trim? Is it an easy round dance night with Harley? Maybe us by the time it gets to him? It’s almost trimmed already? Or is it something where it’s a ton of Calix? Isn’t there, it’s, you know, there’s got to hedge it, that those play a major role in the decision as well. But on just the cultivation style, it’s the look and smell flavor. It’s the test result and the yield. And if it hits all those, those three things, then it’s going on my it’s going to the lineup, for sure.

Speaker (FOHSE)

How often do you sacrifice the strength of the flower over the flavor profile? Or the makeup of it? Because sometimes that’s a huge gamble that I noticed with a lot of brands is if it’s strong, and it’s good, they don’t really care about the flavor profile, how it feels, you know?

Speaker (Kevin Kuethe)

Yeah, I think there’s a lot to be said for how unique a flavor profile can be, or an aroma and terpenes profile. It’s just because there’s so much variation in cannabis. It’s crazy, you know, some garlic sauce tastes like cherries. So smell like dogshit you just never know what you’re right. So it’s crazy divers. So I think that’s continually interesting. And I know that people enjoy that as well. You have to remember that everybody’s trying to get a face plant blessed when exactly, some people are just trying to relax, have a mellow, high, they don’t need to have crazy high THC, it can just be a really nice flavor and aroma and good. But I think cannabis is for everybody to consume, you know. And I truly believe that. And I think that there’s some way to consume for everybody, it’s going to benefit you, in a health sense, and especially long term.

Speaker (FOHSE)

So I think that there’s something for everybody. But like I said back to you, as a commercial grower, I’m trying to find the ones that are going to make more that are going to a be fantastic strains, but that are going to be profitable for the company. And those are typically higher THC strains that are higher yielding. So obviously without giving up too much bet and Brandon for the future, what do you see? Or how do you see Fohse impacting cultivators and business partners like Kevin, and with the products that we continue to innovate and offer in the future? Like how do you see that shifting that relationship?

Speaker (FOHSE)

Yeah, I think it’s just constantly built around work, we can provide value where we can provide support and what problems we could help them solve. Like everything you see from the features and functionalities on our controller or the API switching spectrums. It’s all come from us doing experiments or having Kevin go, why don’t you have this on there? And we go, that’s a great idea. Let’s build it. So we just keep asking, well, we can provide whether it be a horticultural team or plant physiologists, you know, new, you know, just cool new toys for people to play with. That’s what we’re here to do. So the more they tell us more, the more you guys give us suggestions, more, we’ll build the benefit again, the more you guys give them suggestions, the more they will build, there’s an opportunity here with being able to build your own products, test them and change them. If you don’t like it.

Speaker (FOHSE)

If someone says, “Hey, this didn’t work.” Alright, going back to the drawing board, Kevin, what about you? What do you see for the future with a brand like FOHSE? How do you continue to benefit from these products?

Speaker (Kevin Kuethe)

Well, I mean, the, well, let’s see, to be honest, I mean, the A three I don’t, right now, I would, even if it came out with something newer, I’d probably just stick with that. Just because just because. Because just because you gotta remember, cannabis plant is not a perennial, it’s an annual plants got one shot, and it’s grown outside, you know, that’s, that’s just nature, and the sun can throw off 2000 PPM D on a regular basis. And not doing that not giving the plant the ability to have that MaxLite energy is you’re selling it short, you know, that light that’s not going anywhere. Right, we spent seven years developing it. Yeah, good.

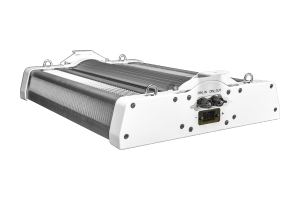

But, you know, to me, I believe that maybe in the earlier stages of the plant’s life, there’s a lot of new technology coming out. And, you know, looking at both the cloning or propagation lights, and what the best light is to use and veg and color spectrums. You know, we’re, there’s a constant debate, especially amongst growers, but, but run and tested being innovative. And that’s one of the things I like about these guys is, you know, if I don’t like something, will, a they’ll provide me with people that are legitimate and third party people that we can talk to that can provide factual scientific information, and then be they can customize and build whatever I want. I’ve, you know, most of the lights I have during my veteran hours, this is something that I asked him to build for me. And, and we love it, you know, so that’s nice having that variability and, you know, seeing what the future brings technology wise, but I don’t know how the girl is gonna get better.

Speaker (FOHSE)

Yeah, and what he’s talking about in that third party. That’s what we brought. Like Oren, for two and a half days to his facility, flew them out there. And we were literally trying to figure out the veg spectrum, what is the best spectrum for veg and intensity. And we did photomorphogenic responses on, I don’t know how many different genetics and different stages of plant life and came to him with a book like this big on his genetics. And we went through it, we bought a couple more test pictures out and we actually ended up making a couple tweaks. And next, you know, you know, our very Spectrum was probably designed by cut four years ago, five years ago. Yeah, pretty well.

Speaker (FOHSE)

This is great. I think one of the biggest things that I will tell you guys to take away from this episode is it’s two pieces here, be patient, when when you have a product or when you have something, take your time, really study the industry get the data that you need, as Kevin said, he took the time to really get the information that he needed from his. I’m drawing a blank here, but he got the information that he needed from his facility in his plants to end up getting the proper yields that he wanted, and to get the product and the flower that he wanted. But again, it takes time, it takes patience, and again with FOHSE. Another thing that’s in the silver lining is patience. We didn’t come up with this light overnight. It’s not just one light, there are many lights that fit the needs of whatever you may need. So you know, as you look forward to many more episodes, there’ll be more education, more information. Look for more clips from this episode, but in the meantime, make sure you tune in next week for Welcome to the future. There will be more coming from us, Kevin, thanks for sticking in with us and happening in pleasure. Thanks for having me. Go for them anymore. Thank you

![“If You’re Going To Go BIG, Go FOHSE!” – Belushi’s Farm CULTIVATION [HIGH]LIGHT](https://resources.fohse.com/wp-content/uploads/2022/03/BELUSHIS-FARM-CLIENT-HIGHLIGHT-1024x576.png)