When it comes to optimizing light for indoor plants or greenhouse cultivation, growers are often bombarded with acronyms: PAR, PPFD, DLI. Understanding the differences and relationships between them isn’t just academic; it’s essential for producing strong yields, maintaining plant health, and getting the most out of your lighting investment. We believe empowered growers are successful growers. So let’s break it down.

What Is PAR?

PAR (Photosynthetically Active Radiation) refers to the spectrum of light (specifically, wavelengths between 400 and 700 nanometers) that plants use for photosynthesis. Think of PAR as the quality of light, it’s the range plants care about when converting photons into chemical energy.

It’s important to note that PAR isn’t a measurement on its own; rather, it’s a description of the usable range of light. You’ll often hear people talk about “PAR levels,” but what they’re really referring to is PPFD, the actual measurement of PAR light that’s hitting the plant.

Many grow lights emit light beyond the PAR range, Far Red (FR) (infrared (IR)) or ultraviolet (UV), which may serve niche purposes (like stress signaling or pest deterrence) but do not directly drive photosynthesis. That’s why optimizing your light spectrum specifically within the PAR range is crucial for growth efficiency.

PPFD: Measuring the Intensity of PAR

PPFD (Photosynthetic Photon Flux Density) tells you how many photons within the PAR range actually reach your plant canopy every second. It’s measured in micromoles per square meter per second (μmol/m²/s).

Put simply, PPFD = light intensity at plant level

If PAR is the type of light plants need, PPFD is how much of that light your plants are getting right now, at a specific location and height. Just like sunlight intensity changes throughout the day, artificial light distribution changes depending on distance from the source, reflector design, and even how crowded your canopy is.

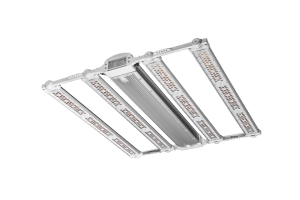

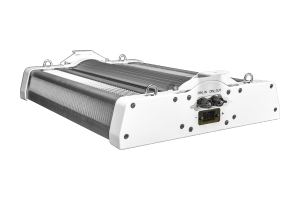

We design lighting systems with optimized optics to ensure even PPFD distribution across the grow space, reducing hot spots and ensuring uniform development across your crop. A light with a high PAR output but poor PPFD distribution can lead to underdeveloped plants on the edges of your grow and burned tops in the center.

DLI: Total Light Exposure Over Time

DLI (Daily Light Integral) is the total amount of PAR light a plant receives over a 24-hour period. It’s measured in mol/m²/day.

Where PPFD is a snapshot, DLI is the time-lapse. It answers the question: How much light did my plant receive today?

You calculate DLI by taking the average PPFD your plant receives and multiplying it by the number of seconds your lights are on each day. The formula is:

DLI (mol/m²/day) = (PPFD μmol/m²/s × light hours × 3600) ÷ 1,000,000

Let’s say your grow light delivers 800 μmol/m²/s of PPFD, and you run your lights for 18 hours a day:

DLI = (800 × 18 × 3600) ÷ 1,000,000 = 51.84 mol/m²/day

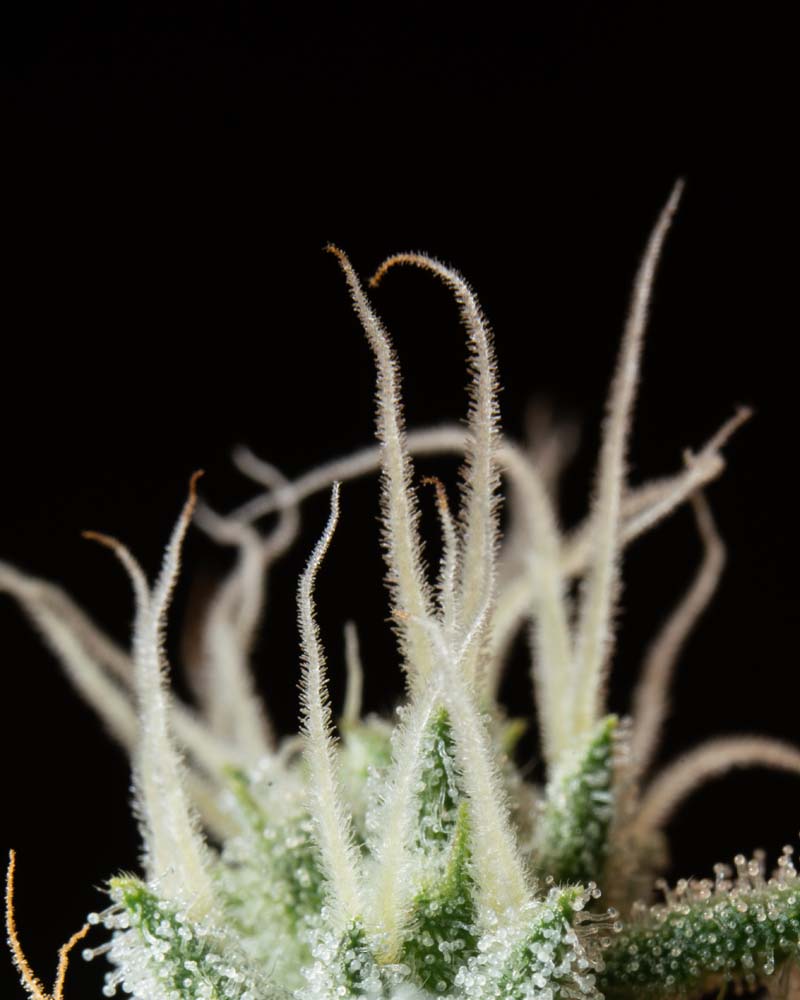

Different plant species, and even different growth stages, require different DLI levels. For example, leafy greens like lettuce thrive around 12–17 mol/m²/day, while cannabis in flowering often needs 40–60 mol/m²/day or more, depending on cultivar and environment.

Why These Metrics Matter for Growers

Understanding PAR, PPFD, and DLI lets you stop guessing and start dialing in your environment for precision performance.

Here’s how:

- Dialing in vegetative vs flowering phases: Vegging plants generally require less intense light (lower PPFD and DLI) than flowering plants. Knowing these values helps you adjust accordingly.

- Avoiding light saturation and stress: Plants can only process so many photons. Once you exceed their photosynthetic capacity, excess light leads to stress, photobleaching, or energy wasted as heat.

- Maximizing efficiency: High-wattage lights aren’t always better. A system with high PAR output and poor light distribution can result in low usable PPFD. Meanwhile, a well-designed system delivers high PPFD uniformly, maximizing your return on light investment.

- Benchmarking and scaling: DLI gives commercial growers a consistent baseline to work from when replicating success across multiple rooms or facilities.

How FOHSE Optimizes for PAR, PPFD & DLI

We design our lights with all three of these metrics in mind, because they work together. Here’s how our technology gives growers the edge:

1. Spectral Engineering

We fine-tune our fixtures to optimize the PAR spectrum for your specific crop. Whether you’re growing leafy greens, strawberries, or premium cannabis, we offer spectral tuning that aligns with your plant’s needs at every stage of growth.

2. High-Output Optics

Many lights lose intensity as you increase mounting height or scale your canopy. Our custom optics ensure high PPFD at greater heights, meaning more flexibility in grow room design without sacrificing performance.

3. Uniform Light Distribution

Uneven light means uneven growth. Our lights are engineered for superior uniformity, reducing plant stress, minimizing manual adjustments, and ensuring consistent DLI across the entire grow.

4. Integrated Controls

Through FOHSE’s control systems, growers can schedule light intensity to track natural photoperiods or maximize photosynthetic efficiency throughout the day, keeping PPFD optimal and DLI consistent, without manual recalibration.

Final Thoughts: Light Smarter, Not Harder

You don’t need to be a physicist to use light like one. With a basic understanding of PAR, PPFD, and DLI, you can make more informed decisions about your lighting system and cultivation strategy. These aren’t just technical terms, they’re levers you can pull to improve your yield, consistency, and quality.

At FOHSE, we’re committed to giving you the tools and the knowledge to grow smarter. Because when you understand your light, you control your grow.

Need help optimizing PPFD and DLI for your facility?

Our team of lighting engineers and cultivation experts is ready to design a custom lighting layout tailored to your crop, facility, and goals. Contact us today to get started.

![Transitioning To High Output LEDs | Legion Of Bloom Client [HIGH]LIGHT](https://resources.fohse.com/wp-content/uploads/2021/12/Legion-of-Bloom-Client-Highlight-YT-Cover-1-1024x576.png)