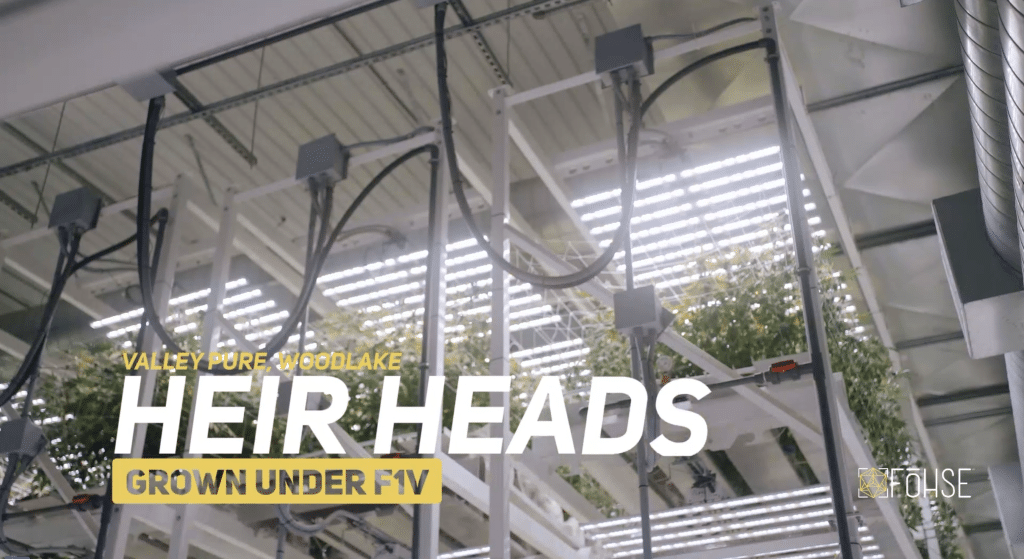

In the heart of central California, the expert cultivators at Green Smart Farmer have developed a revolutionary three-tiered vertical cultivation system, made possible with the F1V LED fixture from Fohse.

As the cannabis industry matures, experienced growers are looking for more advanced ways to maximize their yields. Thanks to improvements in LEDs, vertical growing has become one of the most popular and efficient cultivation methods. The main benefits to growing vertically include increased productivity, a reduced carbon footprint and more cost savings. In this article, we take a closer look at Green Smart Farmer and their state-of-the-art, three-tiered facility powered by Fohse LED lights. It’s a new precedent for vertical grows.

Growing Strong and High

Based in Woodlake, California, Green Smart Farmer grows some of Central California’s hottest cultivars for their Valley Pure dispensaries, in addition to white labeling flower for other brands. Kevin Biernacki, president of Green Smart Farmer, and TJ Hamon, head of cultivation, share how Fohse’s F1V LED fixture is integral to the company’s success.

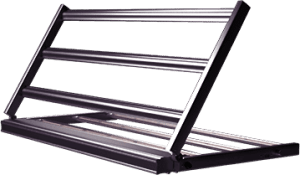

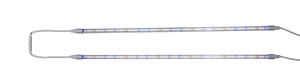

Over 1,600 Fohse F1V lights hang in the 75,600 square-foot space, which also houses their revolutionary three-tiered vertical grow. With 44,320 plants growing per room, this racking system allows for maximum cultivation space.

“Our racking systems, our tray systems and our electrical—everything is designed and built in-house and completely bespoke,” said Biernacki, who brings more than 20 years of cultivation experience. Prior to Green Smart Farmer, he opened The Grove in Las Vegas, where he also worked as their director of cultivation.

“At that time, we were the very first company to go all LED, and we were also the very first company to ever use a vertical rack system,” Biernacki explains.

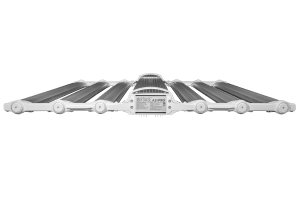

Biernacki’s experience working with vertical grows and LED lights made Green Smart Farmer’s decision to implement Fohse lights easy. The custom-built, moveable racks are designed for optimal airflow through the bottom levels up to the top tier. According to Biernacki, the racks were designed to fit three fixtures in each bay—perfect for the dimensions of the Fohse lights.

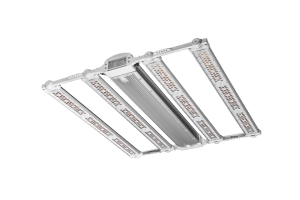

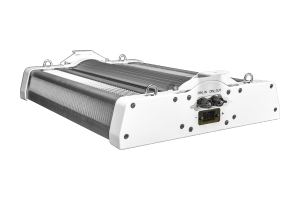

Biernacki went on to explain that the flat profile of F1V light fixtures creates space for the third tier of Green Smart Farmer’s custom-built racking system. And being LED, the thermodynamically balanced F1V lights run cool, so the cultivation team doesn’t need to worry about the heat load on the second and third levels. “The ballast on top has a pretty thin profile without having a lot of bulk in between and allows us to utilize the space and get that third level,” he said.

Cooler lights also remove the need for a cooling system, which keeps the facility’s utility bills and carbon footprint down as low as possible. Being an eco-friendly indoor cultivation facility is a cornerstone of Green Smart Farmer’s mission, Biernacki explains.

“The plants are in biodegradable cocoa cubes; we use a Natafim system for irrigation, that is a super low volume of water,” he said. “Being at the foothills of the Sierra Nevadas also supplies the facility with pristine water.”

Fohse’s F1V: Made for Vertical Environments

For Green Smart Farmer, cutting-edge technology was one of the biggest selling points of Fohse LED systems. Specifically built for vertical grows, the uniform photon density of the F1V is key to calculable crop performance.

“We tried multiple lights and decided on Fohse LEDs for a number of reasons,” Biernacki said. “Fohse is innovative and always ahead of the competition, and when it comes to LEDs, innovation is what it comes down to.”

The functionality of Fohse’s operating system is one of the most significant features. By using a touch screen controller, growers can easily adjust intensity and set automated schedules as the plant moves through grow cycles. By utilizing passive cooling, the fixtures operate at peak efficiency without emitting extra heat on the top tier canopy.

A grow room isn’t the friendliest place for sensitive electronics. For that reason, Fohse LED lights are extremely durable and can withstand hazards found in grow rooms, like water.

“We’ve had a couple of plumbing errors and have probably spilled several hundred gallons of water on a few of the lights—and they’ve continued to operate just fine,” Hamon said.

Hamon explains that due to the range of different cultivars growing in the Green Smart Farmer facility, measuring yield increases from Fohse lights is difficult. However, the higher quality flower resulting from the lights is obvious.

“We do a lot of white labelling for some big companies, so at any given time, we could have anywhere from four to nine different strains in our room,” Hamon said. “We’re currently growing 24 different varieties including our proprietary strain, Watermelon Sugar. What we really look for is quality and terpene profiles, and I can say without a doubt that our cannabis from the Fohse room has had a higher terpene profile.”

Hamon and Biernacki are clearly masters of their craft, and a second 75,600 square-foot replica of the existing building is currently being built at their Woodlake site. This new facility is possible thanks to the success of Green Smart Farmer’s innovative three-tiered vertical grow—and Fohse’s F1V lights.

![[WEBINAR] 7.19 lbs/Light ??How The Grove Attained The Unbelievable](https://resources.fohse.com/wp-content/uploads/2021/12/grovewebinar-1024x576.jpg)