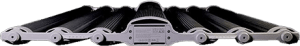

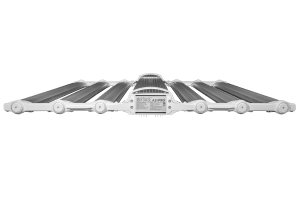

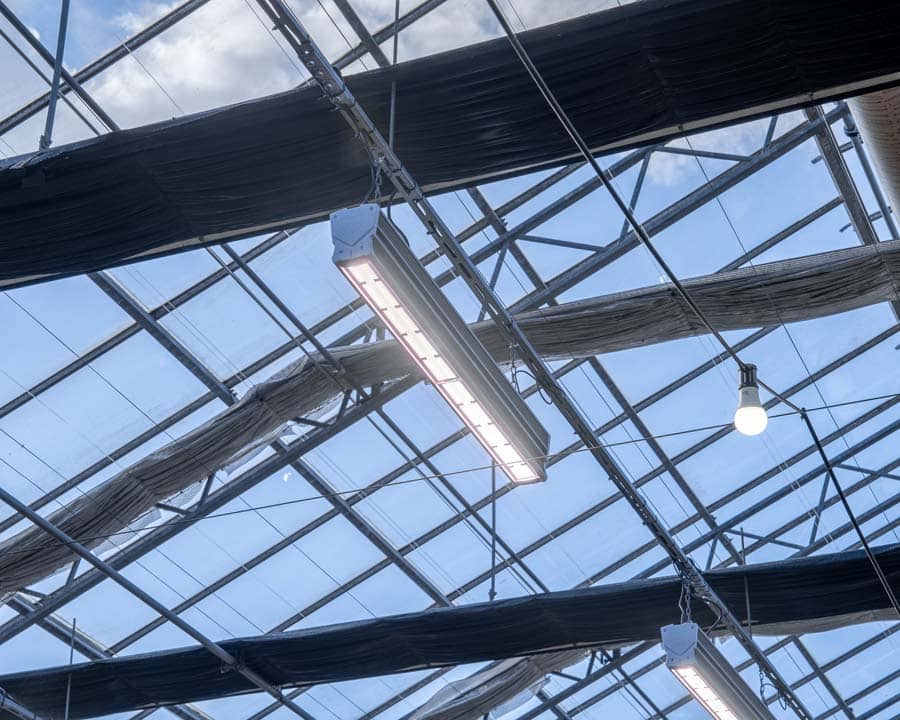

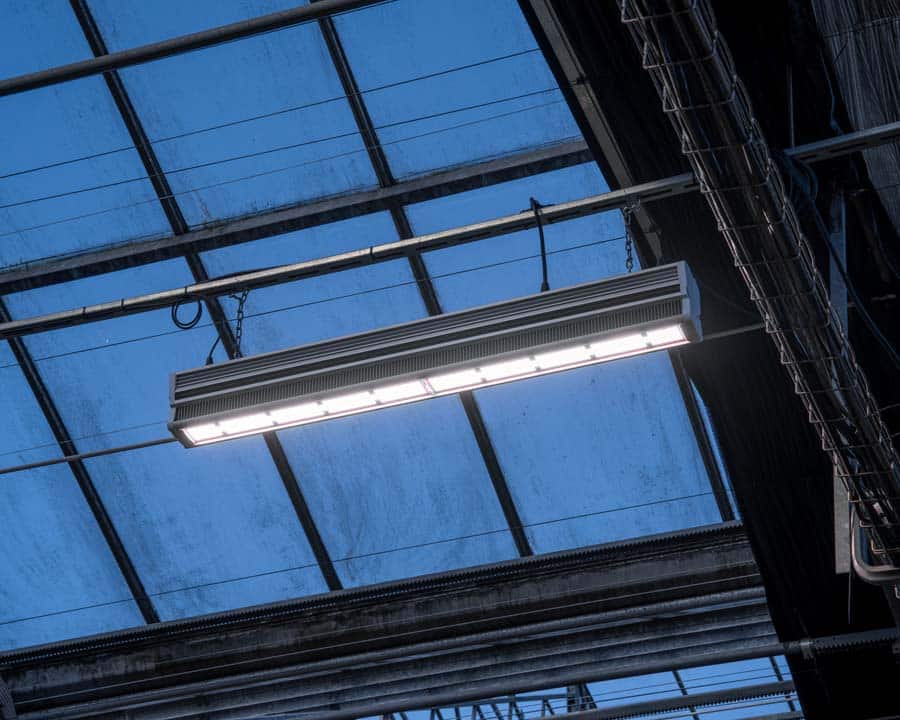

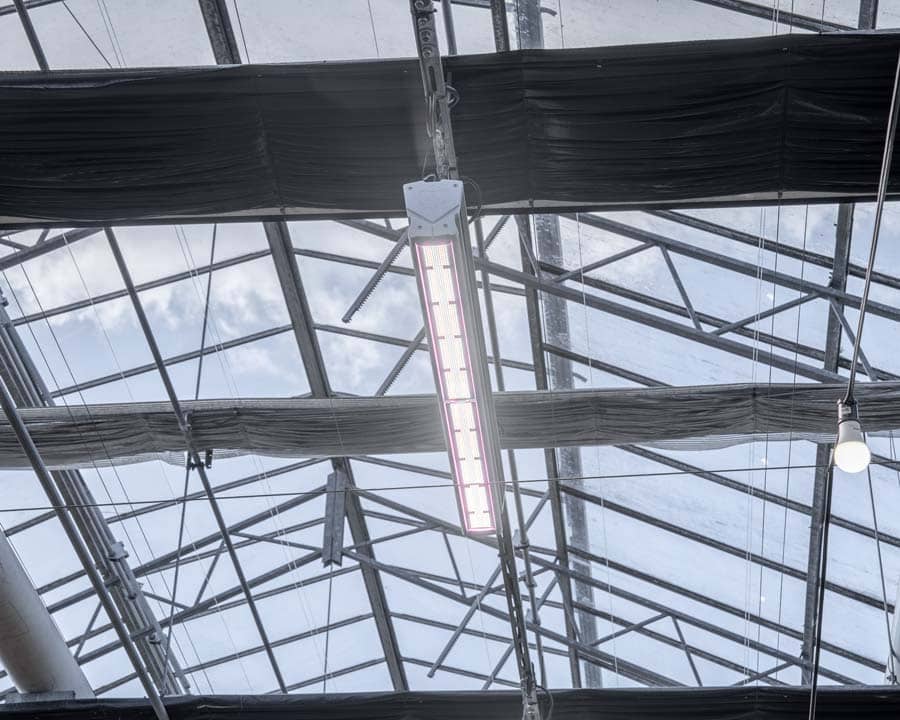

The quantity and quality of light, including the benefits of commercial grow lights, are dynamic and adjustable inputs that regulate plant growth and development. Though HPS has been the trusted cannabis industry standard, growers have been limited by its fixed spectrum and photon output.

High-performance LEDs deliver higher light levels deeper into the canopy, which means the rate of photosynthesis increases. In theory, this can result in greater yield and potency for cannabis. However, your crop will fail without considering other limiting factors that come with increasing light intensity levels.

Growers can experience an array of problems when the light levels are increased, and additional operational changes aren’t made, especially in the context of LED lights vertical farming setups.

Here are a few things to consider as you dial in your LED fixture:

Genetic Selection

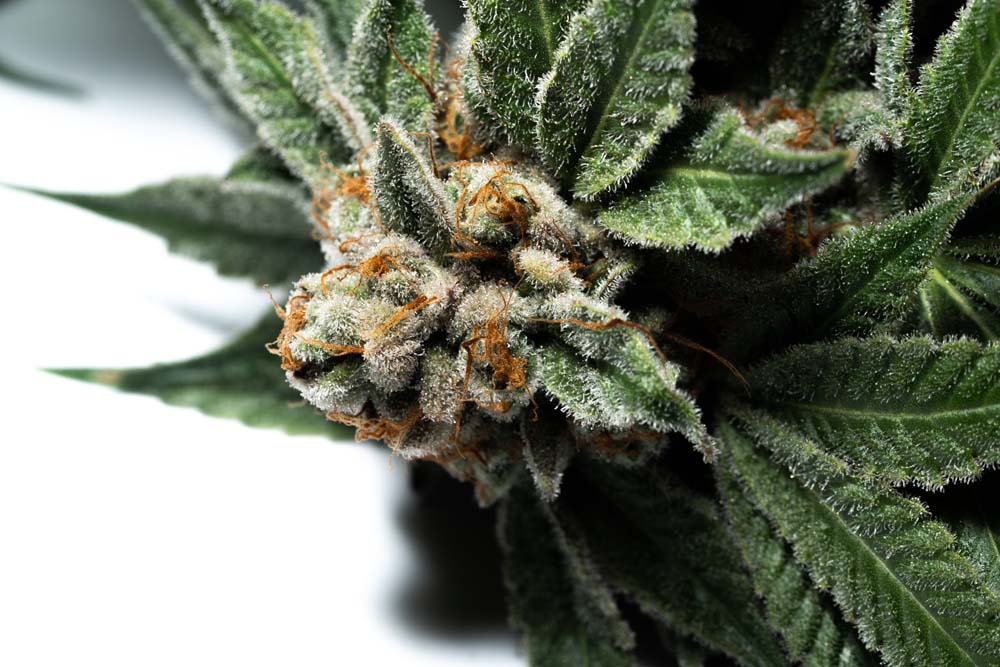

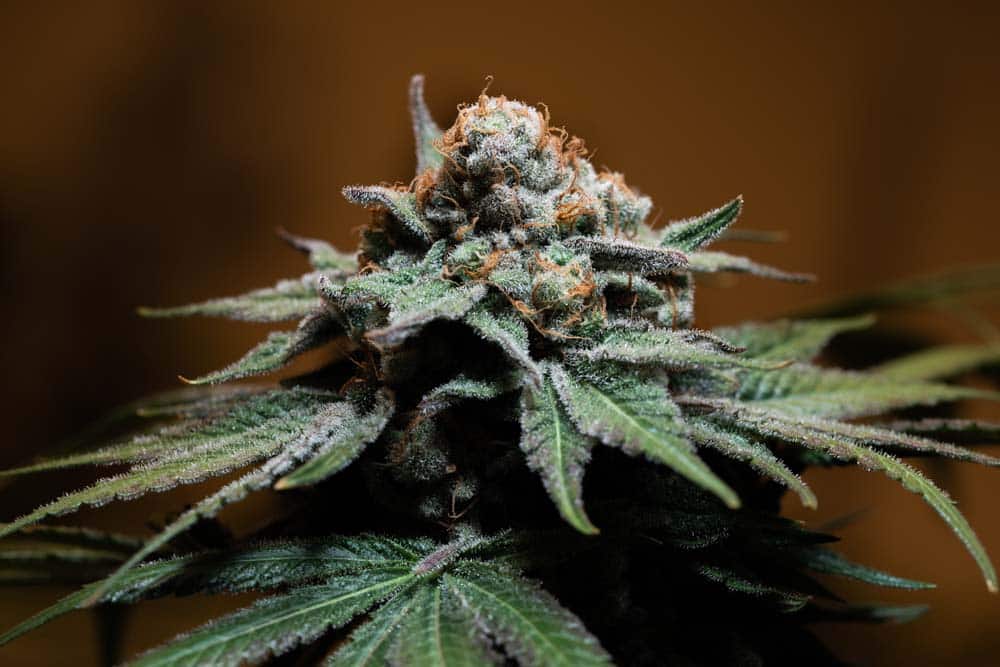

Every cultivar responds differently to photon density, a key aspect to consider when employing commercial grow lights. Certain cultivars began to adapt and prefer higher light levels as cannabis traveled and made its way from cooler and drier regions to hot, equatorial climates. Some varieties, like pure Afghani, remained in cooler regions and kept their preference for lower light. This means certain cultivars have a genetic predisposition against higher light levels, highlighting the benefits of a grow light system in allowing precise control over light intensity levels to match genetic preferences. Your yield will be stunted without considering your genetics as you increase photosynthetic photon flux density (PPFD) over the canopy, a critical factor in LED lights vertical farming applications.

Varieties like Red Congolese and Columbian Gold were created by cannabis moving to equatorial regions with higher light levels and new pathogens. The presence of these new pathogens demanded a need to develop high concentrations of terpenes like limonene and pinene which present potent antibacterial and antifungal effects. Just as cannabis adapted to its environment by producing certain terpene profiles and plant esters, cannabis also adapted to higher light levels, benefiting from the adjustable light intensity levels that commercial grow lights offer.

The goal for long-term success is to identify varieties that are suited for your production cycle and grow well within your facility, taking advantage of the benefits of a grow light system. The key is observation. Success in cannabis cultivation comes from a data-oriented strategy. By taking detailed notes on each variety in the grow and monitoring the ease of post-harvest processing, you can dial in each strain worth keeping and remove ones that present burdens to production, optimizing light intensity levels with LED lights and vertical farming technology for enhanced growth and yield.

Substrate Type

Three media selections often made by home and commercial grow lights users in cannabis cultivation are rockwool, coco, and soil. The type of media you select will greatly affect the way your plants take up nutrients and transpire under higher light levels.

When growing in coco or rockwool, nutrient availability is extremely high. Salt-based fertilizers are manufactured to be immediately available to the root system. Organic amendments need a colonized system of microorganisms within the soil that needs time to break the amendments down into a plant-usable form. This can become an issue when using organic amendments because they can take weeks to become available to your plant. However, balanced soil systems are able to regulate pH and nutrient uptake with less input needed from the gardener.

Field capacity is the amount of water content held in the medium. In these three substrates, field capacity varies greatly. For many growers using commercial grow lights in their cultivation setups, understanding these water retention differences is essential.

Hugo’s by Grodan, for example, has a maximum field capacity of 78% and below 30% runs the risk of developing dry, salty channels within the media. If you drop lower, your media will develop hydrophobic properties. Rockwool also seems to maintain a consistent field capacity with very little variation from vendor to vendor. It’s a sterile media and begins at a neutral pH which makes it very appealing to indoor cultivators using a grow light system.

Natural variations in coconut coir may shock growers who aren’t anticipating it. Coco comes in varying blends of three ingredients: husk, pith, and chips. Achieving uniformity when hydrating can be difficult due to the weight of the substrate or how it was processed by the vendor. Finely shredded coco will have a higher field capacity around 60% while coco made with chunks of fiber will hover around 50%-55%. So not only does field capacity vary between substrates but can also vary between brands, batches, and grades of the same type of media. This variability is an important factor to consider when integrating LED lights vertical farming practices.

The field capacity of potting soil greatly varies depending on the contents of the blend. Peat-perlite blends have around a 72% field capacity while peat-vermiculite blends average around 80%. Blends with perlite will have greater amounts of variance in field capacity as opposed to blends with vermiculite. Peat blends with more sand and chunks/chips will have a lower average field capacity around 60%.

Consider how your media will be influenced by higher light levels and plan an irrigation strategy around these factors.

Fertigation Volume and Concentration

Many growers are eager to test the efficacy of high-output LEDs, specifically LED grow lights for cannabis, after making the switch but don’t account for the necessary increase in total fertigation volume. This is crucial as the benefits of LED lighting include higher light intensity levels, which directly affect plant growth. If shot sizes are not adjusted as light intensity, particularly under LED grow lights for cannabis, increases, the higher rates of photosynthesis and transpiration will cause the field capacity of the media to drop lower than targeted levels. This leads to a premature rise in substrate EC and salt channeling, which can be an issue for cultivars that prefer lower levels of feed and media EC. Understanding the light intensity level benefits of LED lighting is essential in optimizing fertigation practices for cannabis cultivation.

When making the switch from HPS, usually have two goals in mind:

-

Keep my light levels the same, but save on utility expenses

-

Increase my light levels from the limitations of HPS fixtures

In either case, efficient LEDs like those used in commercial grow lights produce and distribute more usable light to the canopy. With an ideal VPD, this will result in higher rates of photosynthesis and transpiration. A quality irrigation system and variety-specific irrigation strategy are instrumental to dialing in crop production under higher light levels.

A quality irrigation system and variety-specific irrigation strategy are instrumental to dialing in crop production under higher light levels. Depending on the plant age and height, you can steer your crop towards vegetative growth or generative growth.

Scheduling short, frequent irrigations with a small shot size and low EC will cue your plant toward vegetative growth. Scheduling less frequent irrigations with larger shot sizes and a higher concentration of available nutrients keeps cannabis production balanced in late flower. This can be beneficial during early flower for developing many bud sites on cultivars that have large internodal spacing. Shot size and EC should transition together with higher light levels in order to control plant morphology and maximize production

Demand for Supplemental CO2

Cannabis plants benefit from carbon dioxide enrichment under commercial grow lights when light levels surpass 850-900 PPFD. Cultivating under HPS requires little supplemental CO₂, as most 1000 Watt HPS fixtures deliver 600-1000 PPFD depending on the footprint.

LED lights vertical farming solutions deliver much higher PPFD levels to your canopy without the excessive heat typically seen when pushing higher light under HPS. With this comes the need to balance the other growing parameters such as CO₂.

When supplementing CO₂ into your grow light system, you should consider the placement of the sensor in order to get the most accurate readings possible. Placing the sensor below plant height ensures the maximum amount of CO₂ is reaching the plant because CO₂ is heavier than air. A small disadvantage will be an increase in CO₂ usage, especially if a carbon filter setup is in place.

Placing your sensor above plant height will be impacted the least by an exhaust or carbon filter. The main disadvantage is this can cause a much higher than accurate reading since Co2 is heavier than air. Cannabis will ultimately lack the ability to make the glucose needed for growth without adjusting CO2 levels and sensor placement resulting in depreciating yields on harvest day.

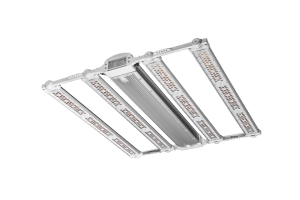

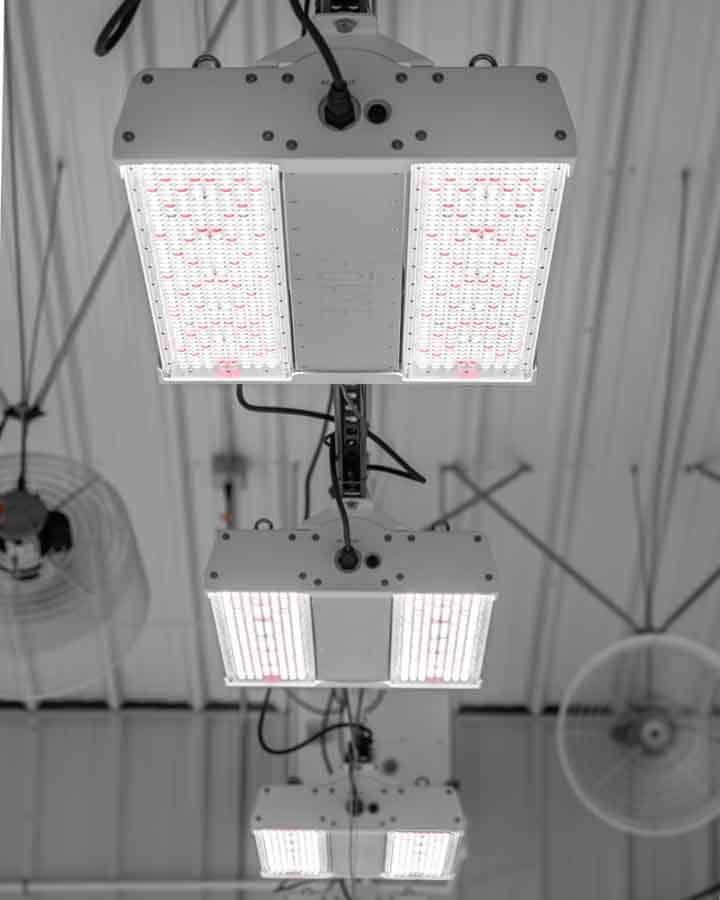

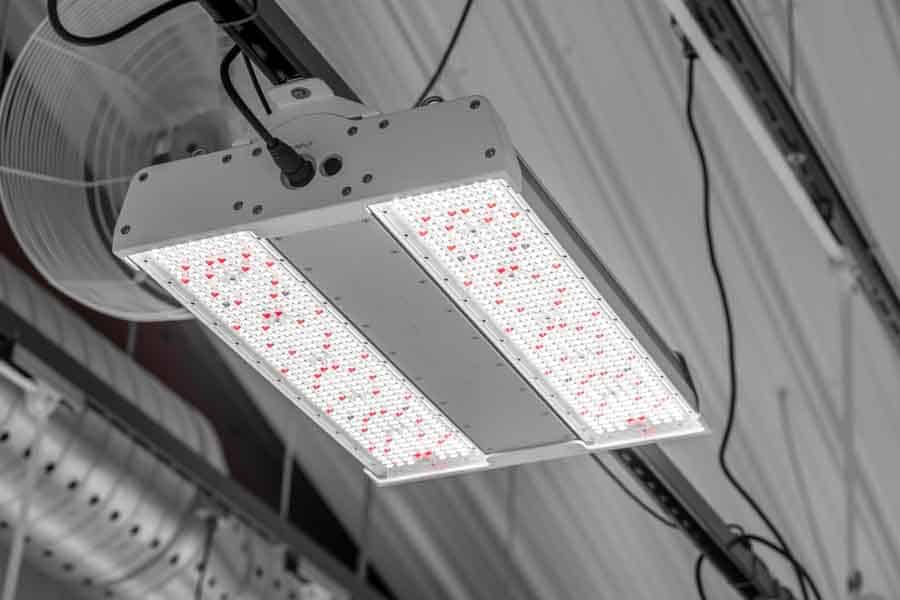

Grow with FOHSE

High-performance LED grow lights for cannabis are more complex than a plug-and-play addition to your cultivation facility. That’s why FOHSE’s cultivation liaisons support our clients’ adjustment to higher light levels, both during the purchasing process and after the transaction is completed, highlighting the benefits of LED lighting.

As growers, our job is to create the proper environment for cannabis to thrive. Increasing your light levels without considering every parameter, including light intensity level, will be detrimental to your final crop.

Proper utilization of all parameters together and collaborative guidance with FOHSE means high-powered LED fixtures & great flowers for years to come, showcasing the benefits of LED grow lights for cannabis.

See our LEDs in action and read how Lume increased their yields by 20% with FOHSE, leveraging the benefits of LED lighting and optimal light intensity levels.

Written by Anthony Domangue, Grower Liaison at FOHSE, Inc.

Want more? Check out our Webinar with Anthony as he explains: